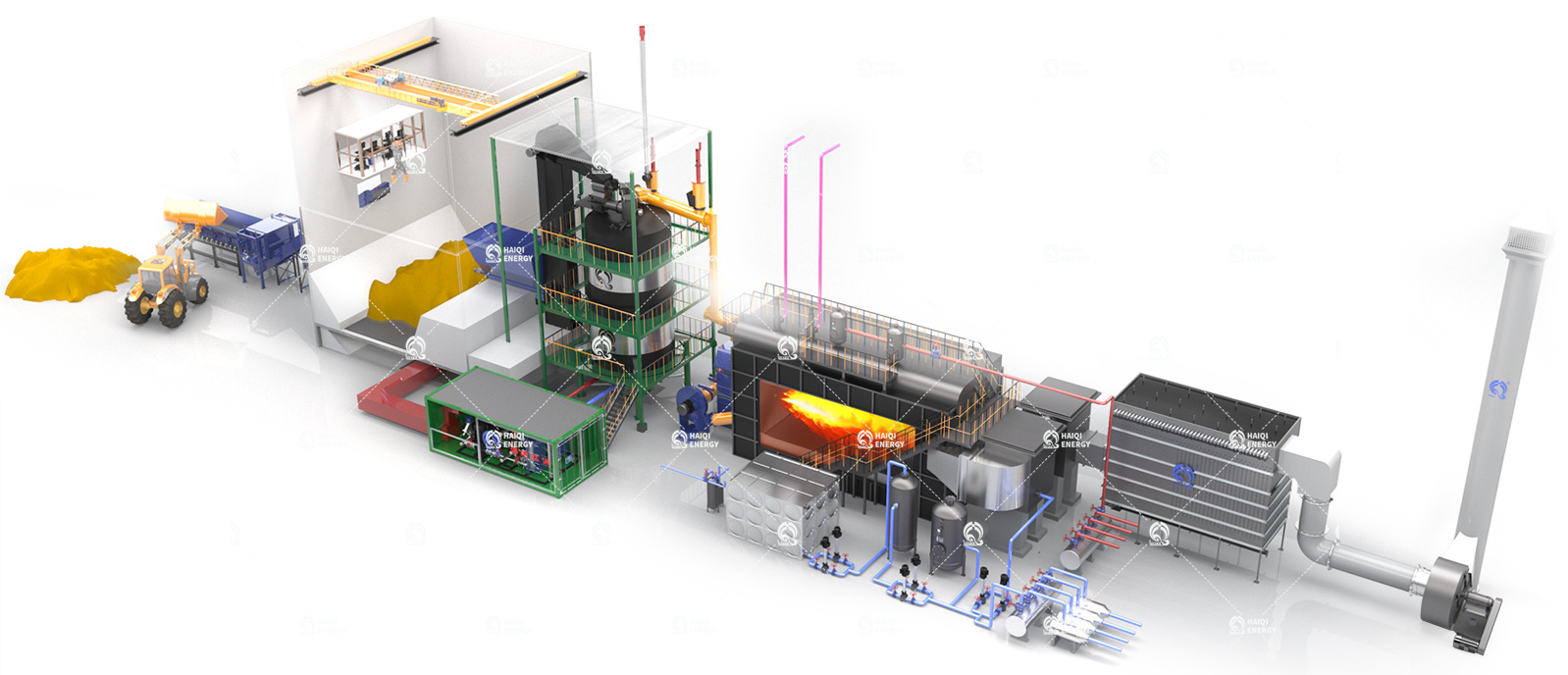

Haiqi has launched a skid-mounted biomass gasification system in order to reduce the total EPC cost of EMC projects in response to market demand at home and abroad. The advantages of this system can reduce the total EPC project volume by more than 90%. It greatly shortens the construction period, advances the overall progress of the project, and helps EMC enterprises and energy-consuming enterprises to solve the problem of energy consumption time. It is also convenient for project site management, which greatly saves time and money for the project.

The system consists of three major components, namely gasification system, combustion system and control system. The system occupies a small area and the installation speed is fast. When the equipment arrives at the site, it is only necessary to hoist the large skid-mounted system in the designated position. The water and gas circuit pipelines and the construction site can be quickly installed according to the drawings, and all the installation work can be completely completed within a week. There is no need to build additional workshops and control rooms, and all systems have their own roofs, so there is no need to build workshops for equipment.