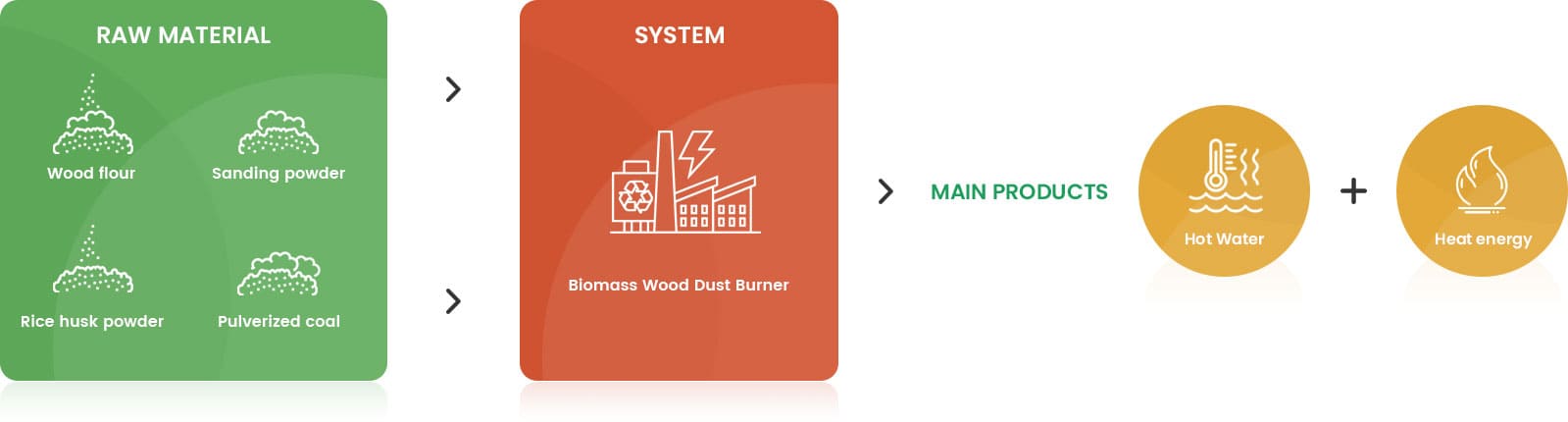

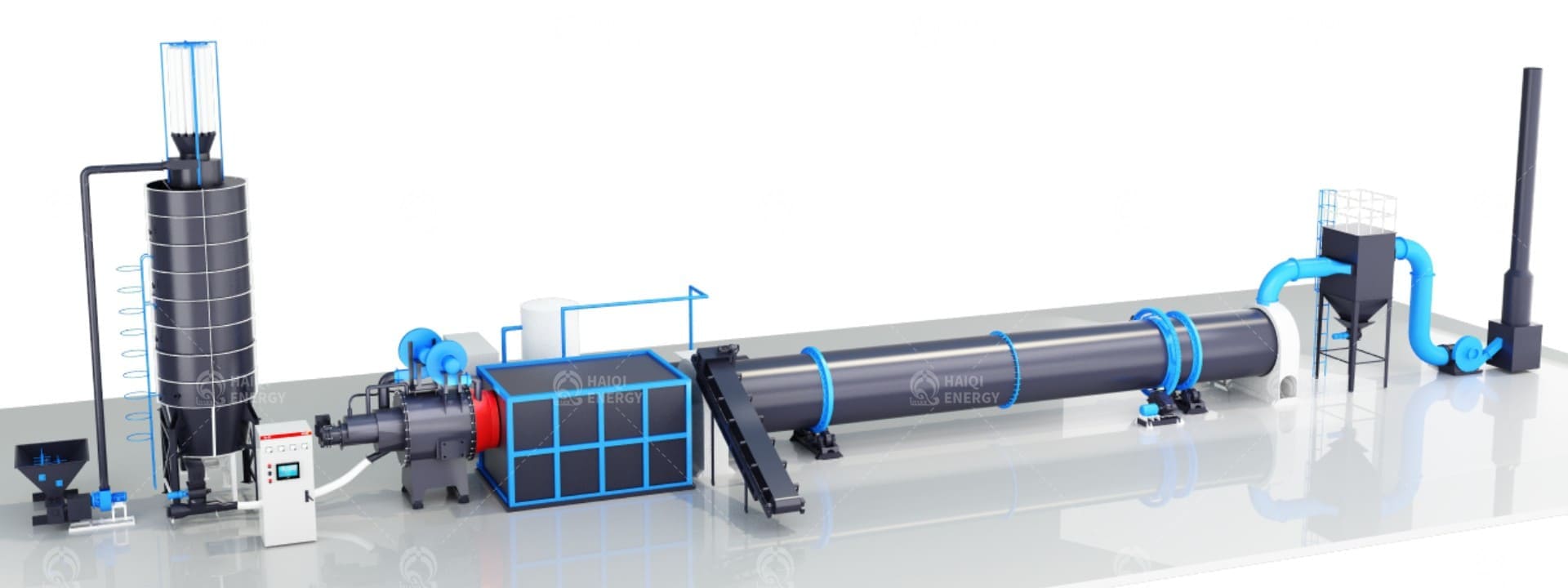

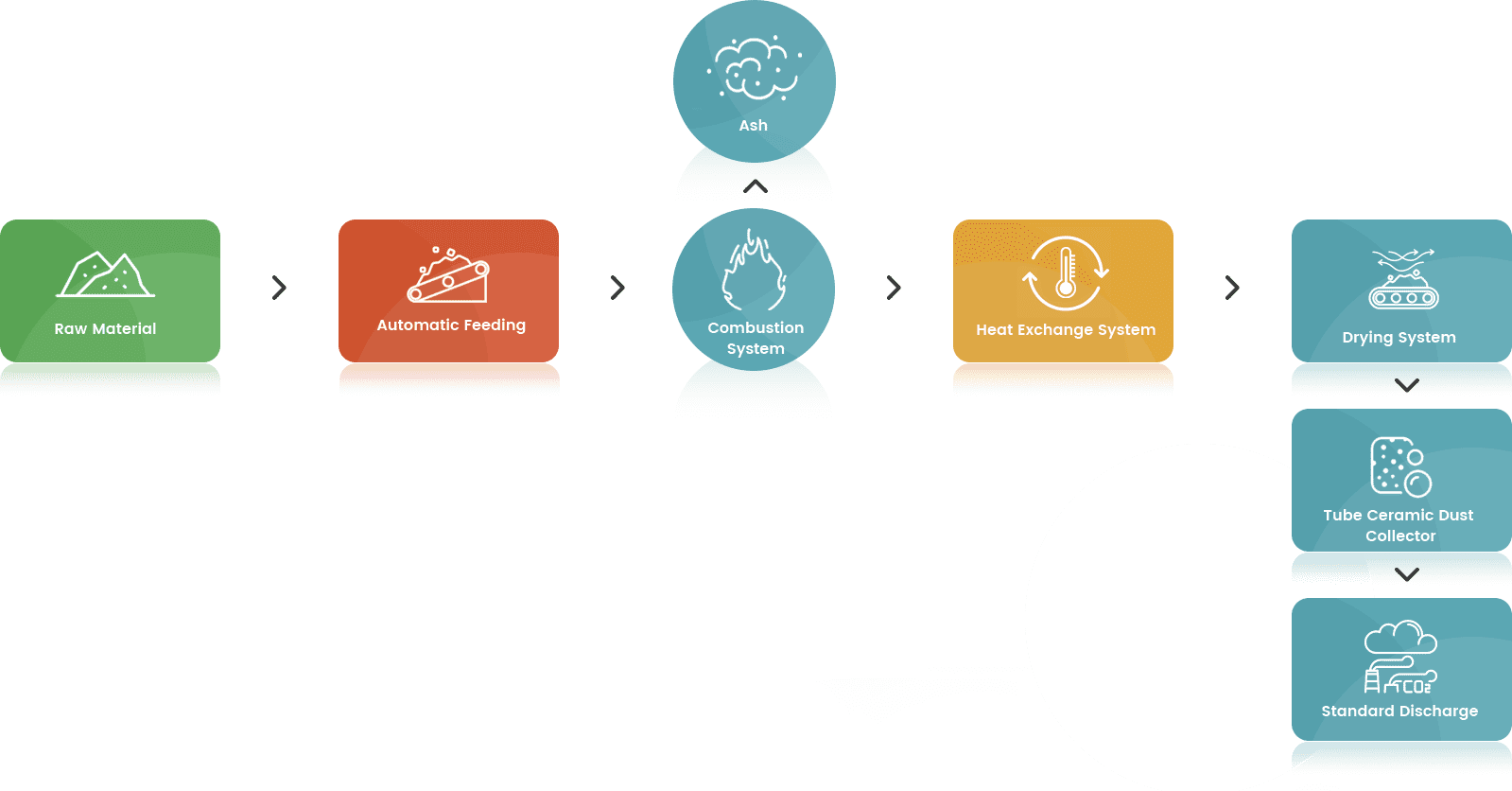

System Diagram

Biomass Dust Burner Docking Boiler System

1. Screw Feeder

2. Silo

3. Control Cabinet

4. Wood Powder Burner

5. Heat Exchanger

6. Dryer

7. Multi-Tube Ceramic Dust Collector

8. Induced Fan

9. Chimney

1

Screw Feeder

2

Silo

3

Control Cabinet

4

Wood Powder Burner

5

Heat Exchanger

6

Dryer

7

Multi-Tube Ceramic Dust Collector

8

Induced Fan

9

Chimney

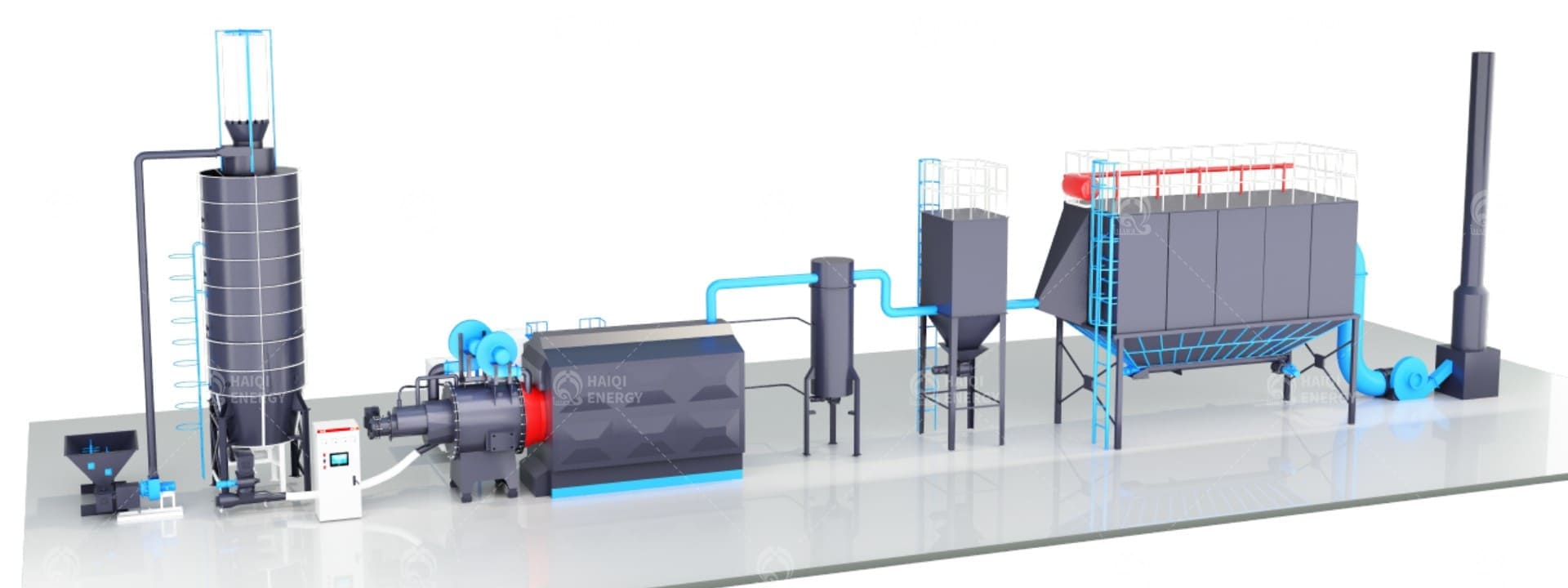

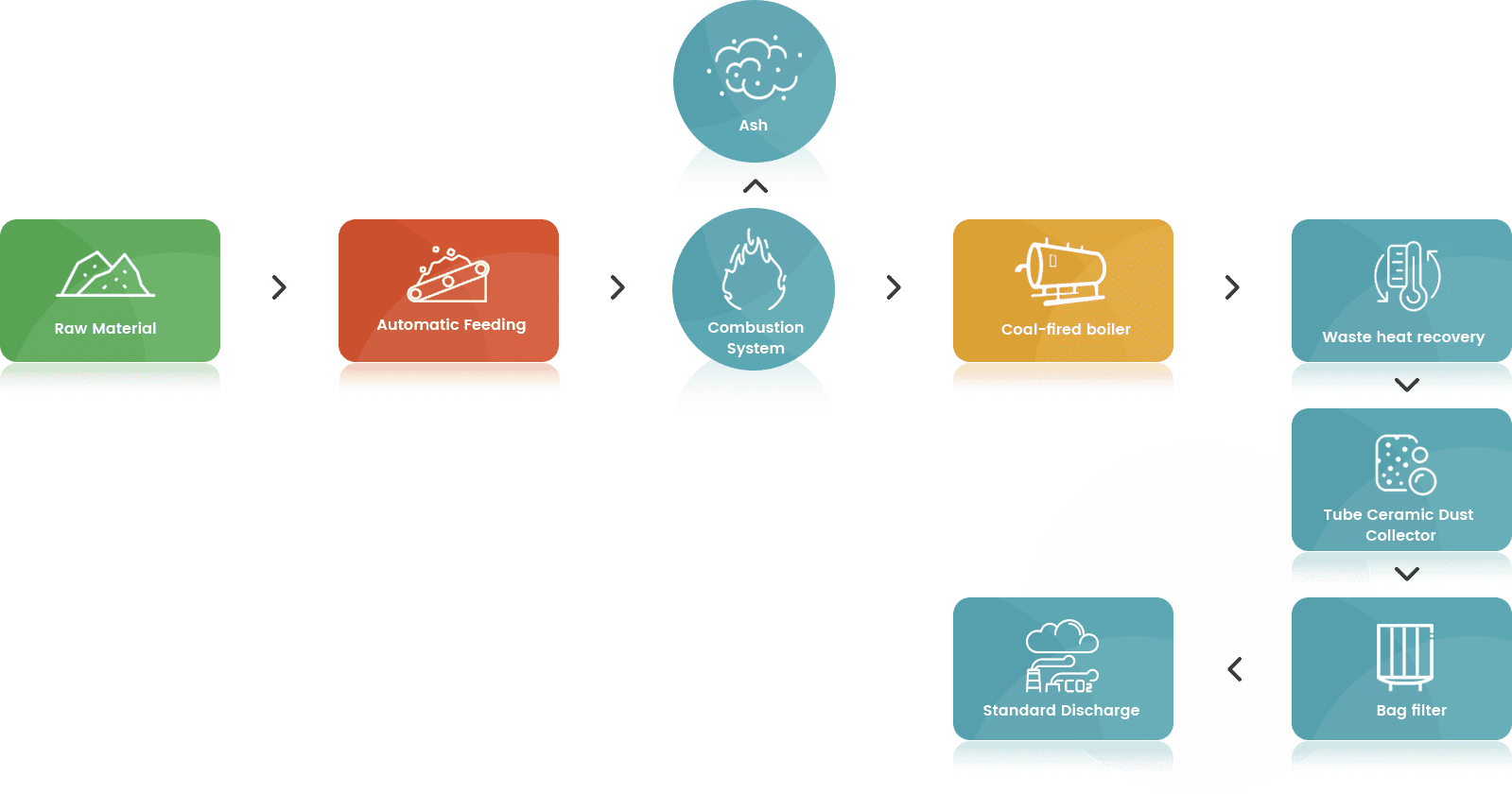

1. Stirring Feeder

2. Silo

3. Control Cabinet

4. Wood Powder Burner

5. Coal-Fired Boiler

6. Waste Heat Recovery

7. Multi-Tube Ceramic Dust Collector

8. Bag Filter

9. Induced Fan

10. Chimney

1

Stirring Feeder

2

Silo

3

Control Cabinet

4

Wood Powder Burner

5

Coal-Fired Boiler

6

Waste Heat Recovery

7

Multi-Tube Ceramic Dust Collector

8

Bag Filter

9

Induced Fan

10

Chimney

1. Stirring Feeder

2. Silo

3. Control Cabinet

4. Wood Powder Burner

5. Oil Gas Boiler

6. Waste Heat Recovery

7. Multi-Tube Ceramic Dust Collector

8. Bag Filter

9. Induced Fan

10. Chimney

1

Stirring Feeder

2

Silo

3

Control Cabinet

4

Wood Powder Burner

5

Oil Gas Boiler

6

Waste Heat Recovery

7

Multi-Tube Ceramic Dust Collector

8

Bag Filter

9

Induced Fan

10

Chimney

.jpg)

.jpg)

(2).jpg)

.png)

.jpg)