Haiqi Internal Combustion Biomass Power Generation System

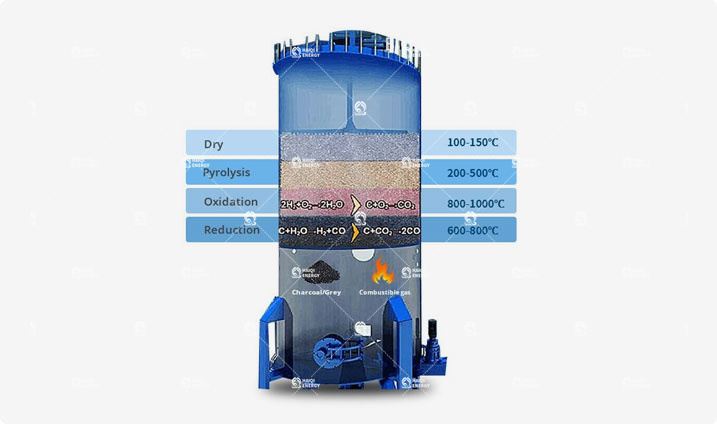

It mainly includes: feeding system, storage and drying system, heat exchange system, biomass gasification system, combustible gas purification system, power generation system, waste heat utilization system, and 5G intelligent energy control system.

Haiqi Biomass Steam Power Generation System

It mainly includes: material feeding system, material storage drying system, biomass gasification system, biomass combustible gas combustion system, gas steam boiler system, steam power generation system, flue gas purification system, and 5G intelligent energy control system.

Haiqi Biomass External Power Generation System

It mainly includes: material storage and feeding system, heat exchange system, biomass gasification system, purification system, Stirling external power generation system, waste heat utilization system, flue gas purification system, and 5G intelligent energy control system.

Haiqi Biomass ORC Power Generation System

It mainly includes: material feeding system, material storage drying system, biomass gasification system, biomass combustible gas combustion system, gas steam boiler system, ORC power generation system, flue gas purification system, and 5G intelligent energy control system.