Generation System

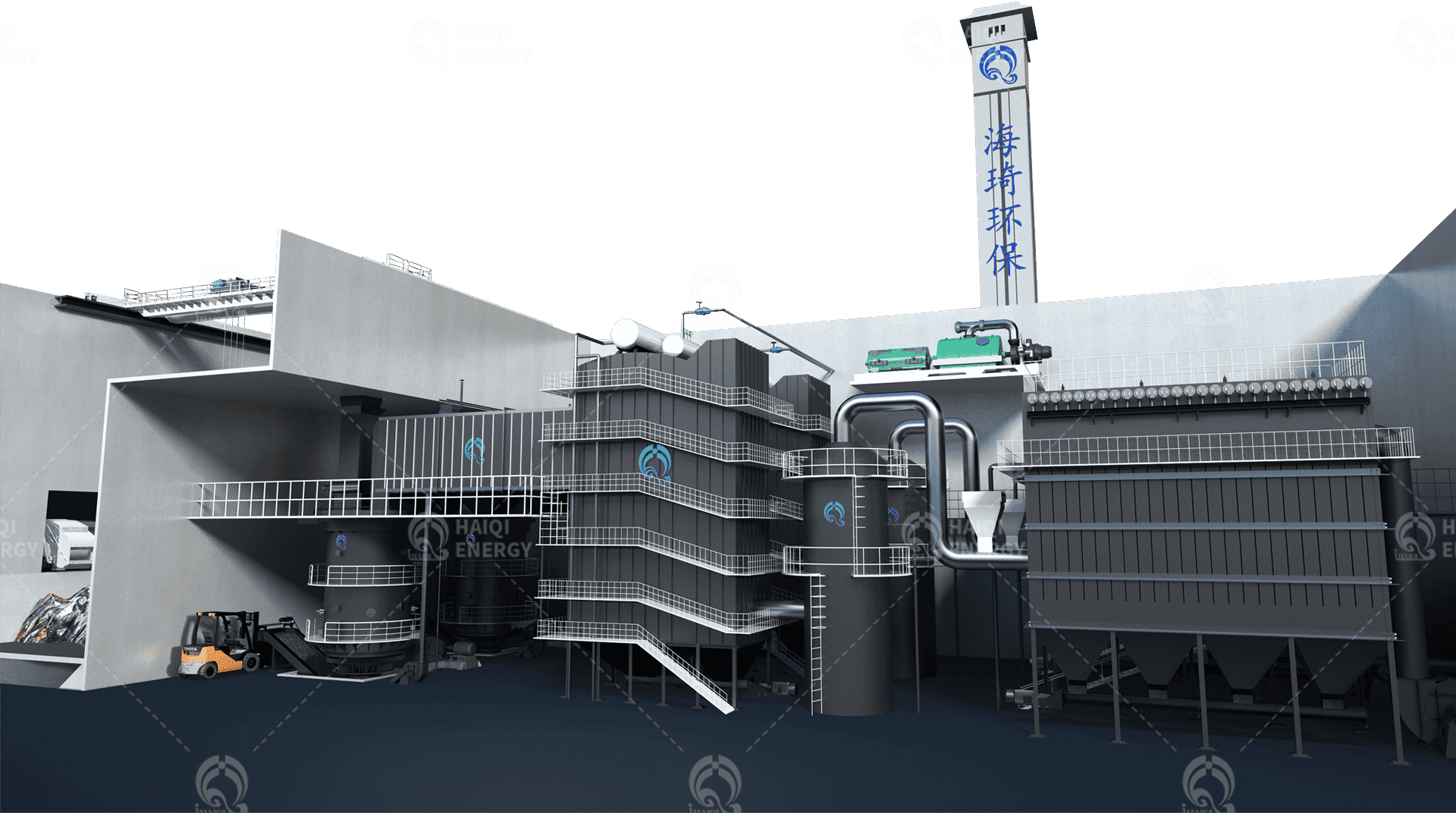

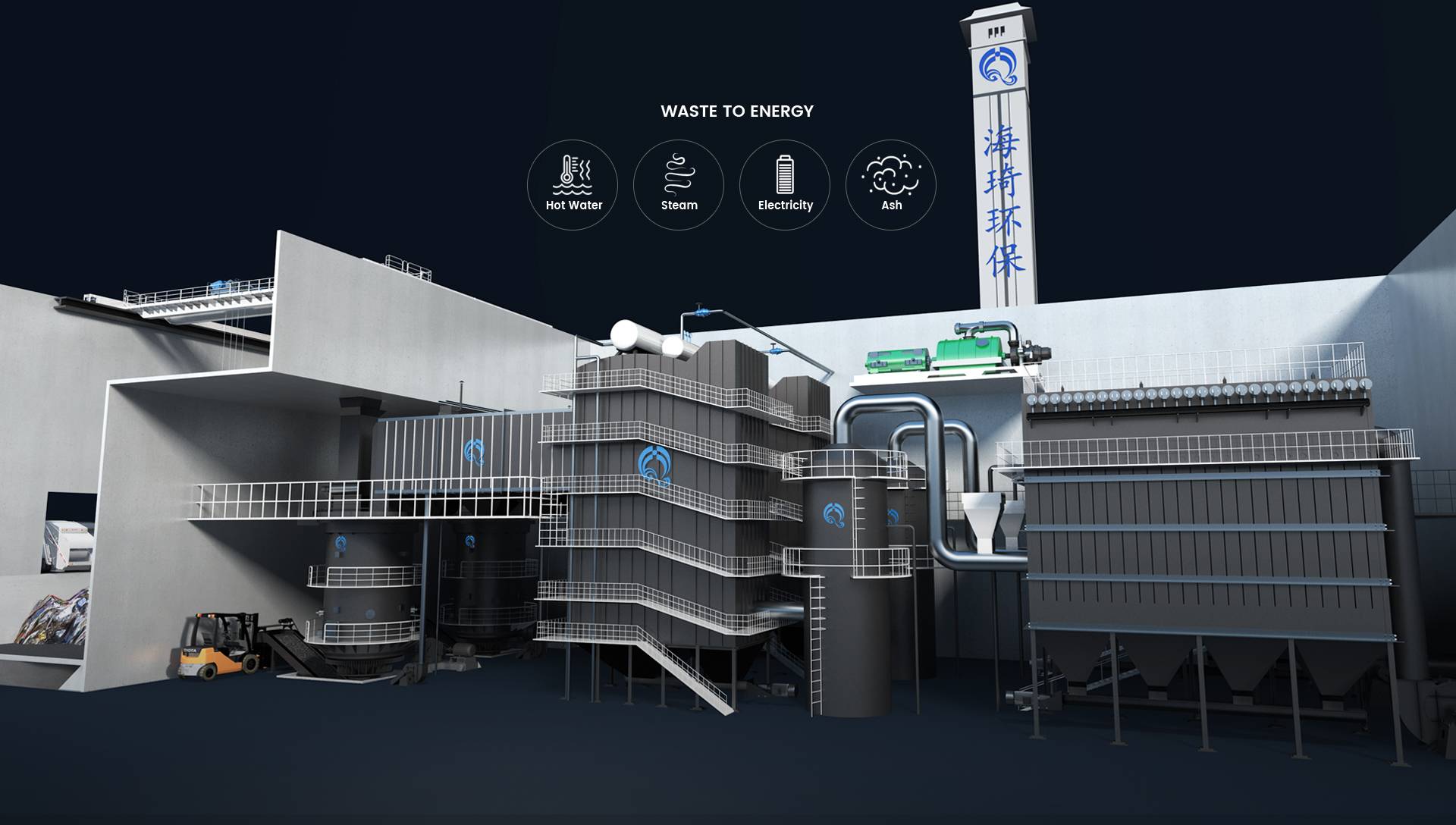

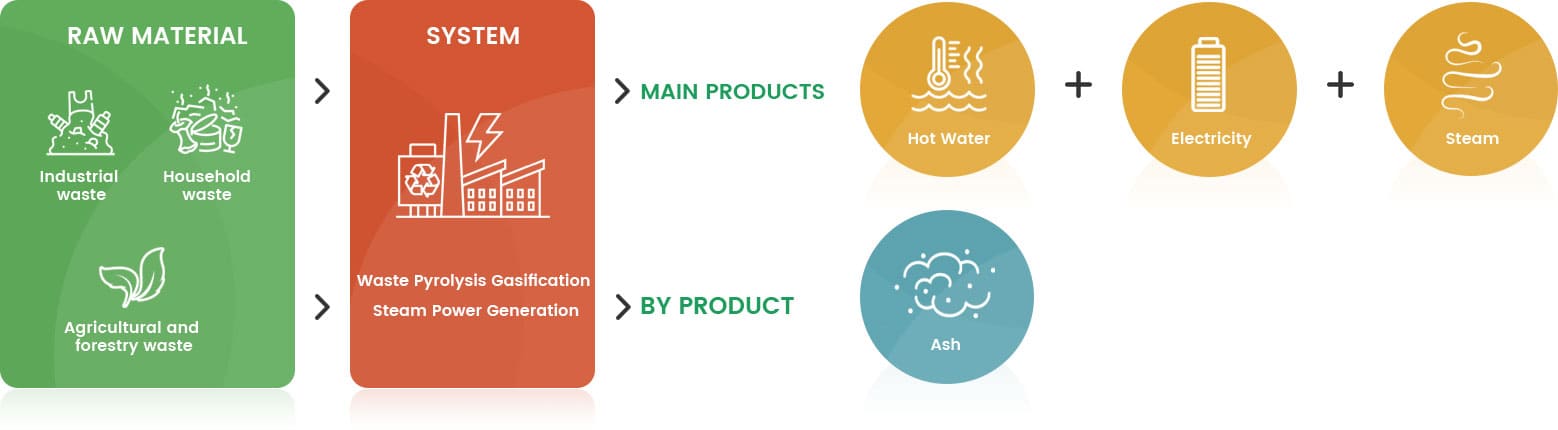

Waste Pyrolysis Gasification Steam Power Generation System

1. Grab Loading

2. Pyrolysis Gasification System

3. Secondary Combustion System

4. Waste Heat Boiler System

5. Deacidification System

6. Activated Carbon System

7. Bag Filter

8. Induced Fan

9. Chimney

1

Grab Loading

2

Pyrolysis Gasification System

3

Secondary Combustion System

4

Waste Heat Boiler System

5

Deacidification System

6

Activated Carbon System

7

Bag Filter

8

Induced Fan

9

Chimney

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).png)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

(1).png)

.png)