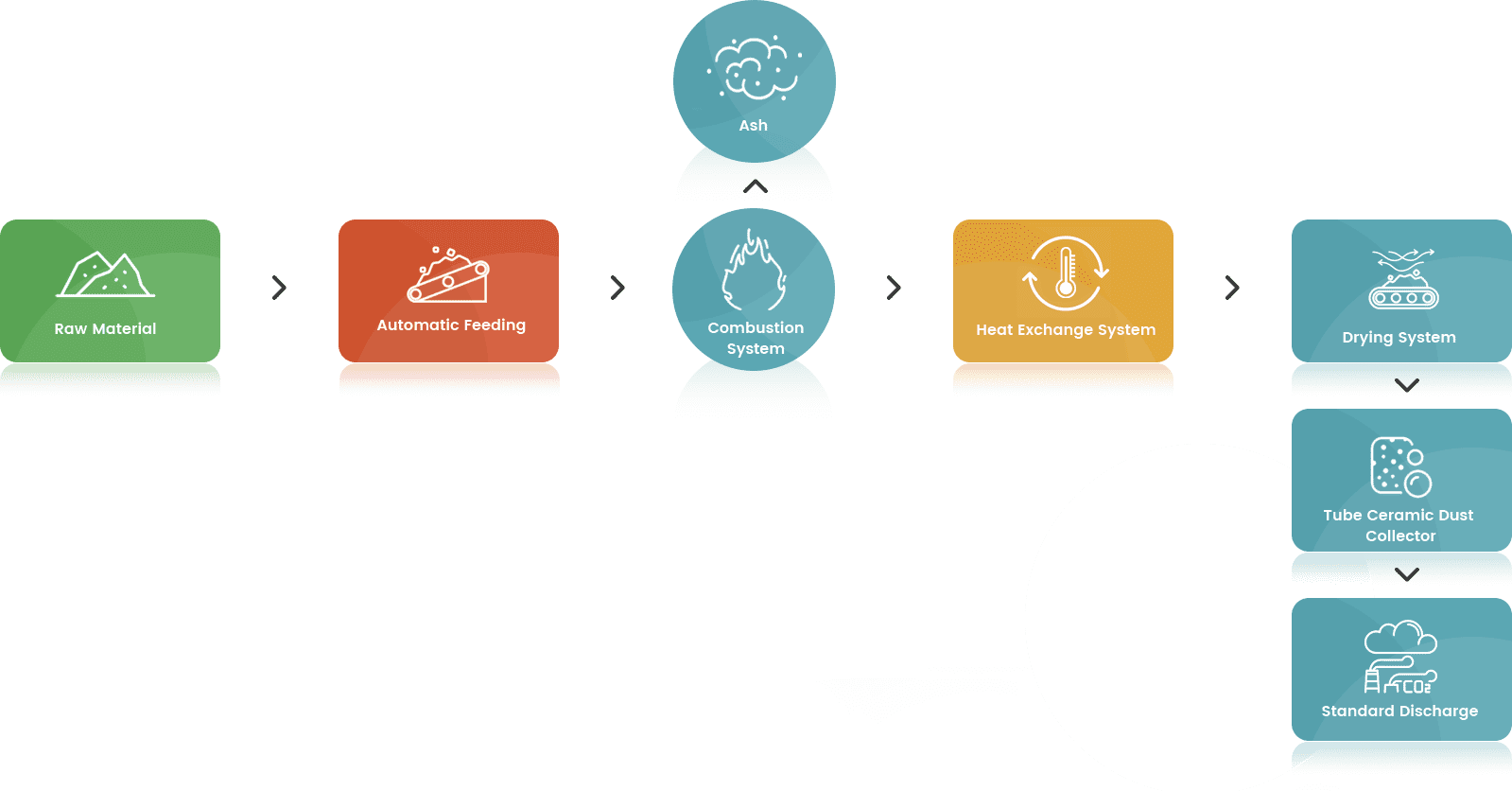

System Diagram

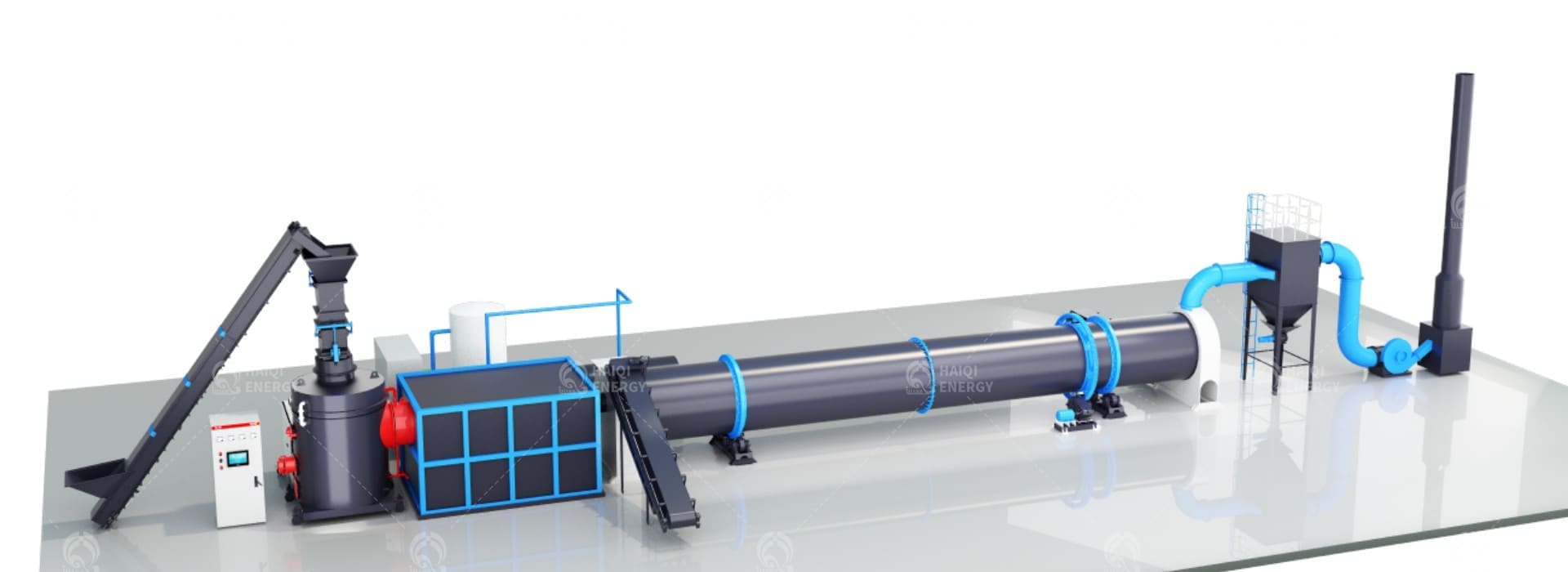

Biomass Chip Burner Docking Boiler System

1. Belt Feeder

2. Pneumatic Copy Feeding

3. Control Cabinet

4. Wood Chip Burner

5. Heat Exchanger

6. Dryer

7. Multi-Tube Ceramic Dust Collector

8. Induced Fan

9. Chimney

1

Belt Feeder

2

Pneumatic Copy Feeding

3

Control Cabinet

4

Wood Chip Burner

5

Heat Exchanger

6

Dryer

7

Multi-Tube Ceramic Dust Collector

8

Induced Fan

9

Chimney

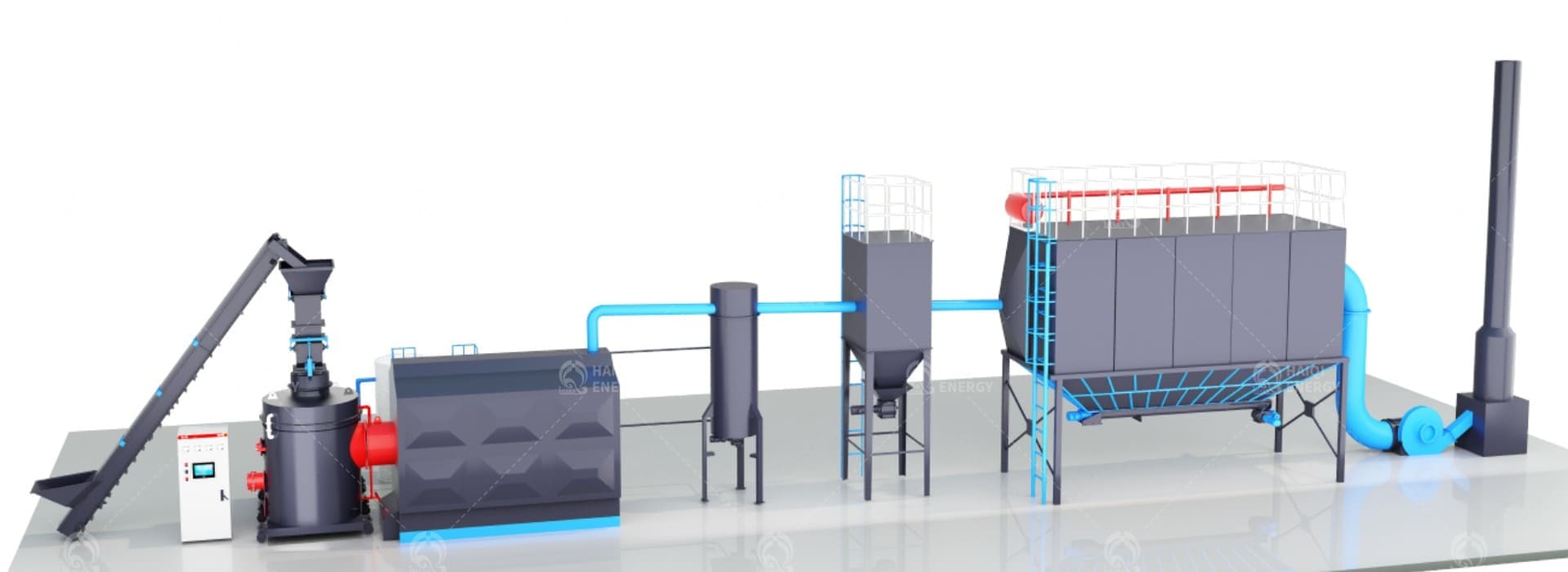

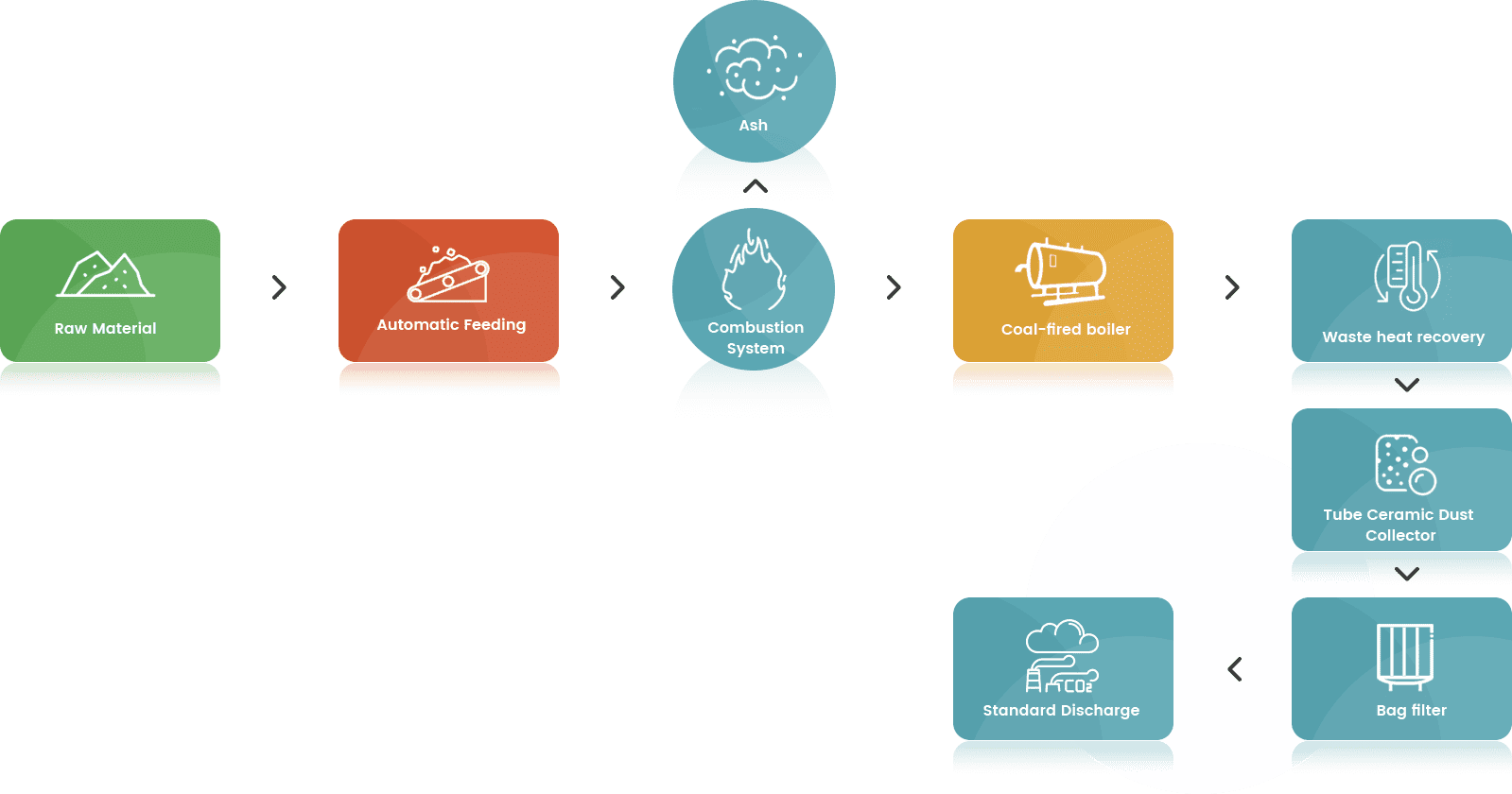

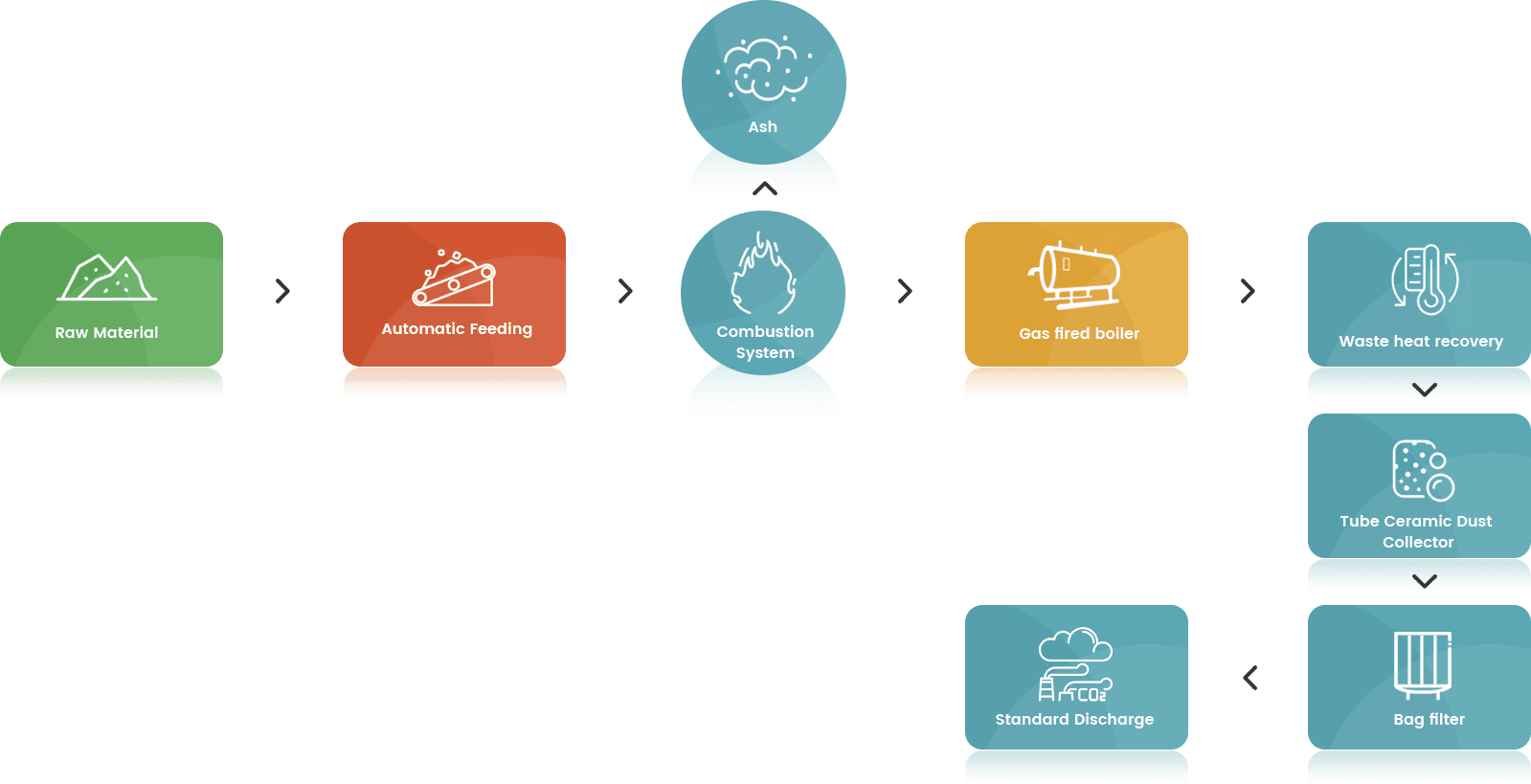

1. Belt Feeder

2. Pneumatic Copy Feeding

3. Control Cabinet

4. Wood Chip Burner

5. Coal-Fired Boiler

6. Waste Heat Recovery

7. Multi-Tube Ceramic Dust Collector

8. Bag Filter

9. Induced Fan

10. Chimney

1

Belt Feeder

2

Pneumatic Copy Feeding

3

Control Cabinet

4

Wood Chip Burner

5

Coal-Fired Boiler

6

Waste Heat Recovery

7

Multi-Tube Ceramic Dust Collector

8

Bag Filter

9

Induced Fan

10

Chimney

1. Belt Feeder

2. Pneumatic Copy Feeding

3. Control Cabinet

4. Wood Chip Burner

5. Oil Gas Boiler

6. Waste Heat Recovery

7. Multi-Tube Ceramic Dust Collector

8. Bag Filter

9. Induced Fan

10. Chimney

1

Belt Feeder

2

Pneumatic Copy Feeding

3

Control Cabinet

4

Wood Chip Burner

5

Oil Gas Boiler

6

Waste Heat Recovery

7

Multi-Tube Ceramic Dust Collector

8

Bag Filter

9

Induced Fan

10

Chimney

(2).jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.jpg)