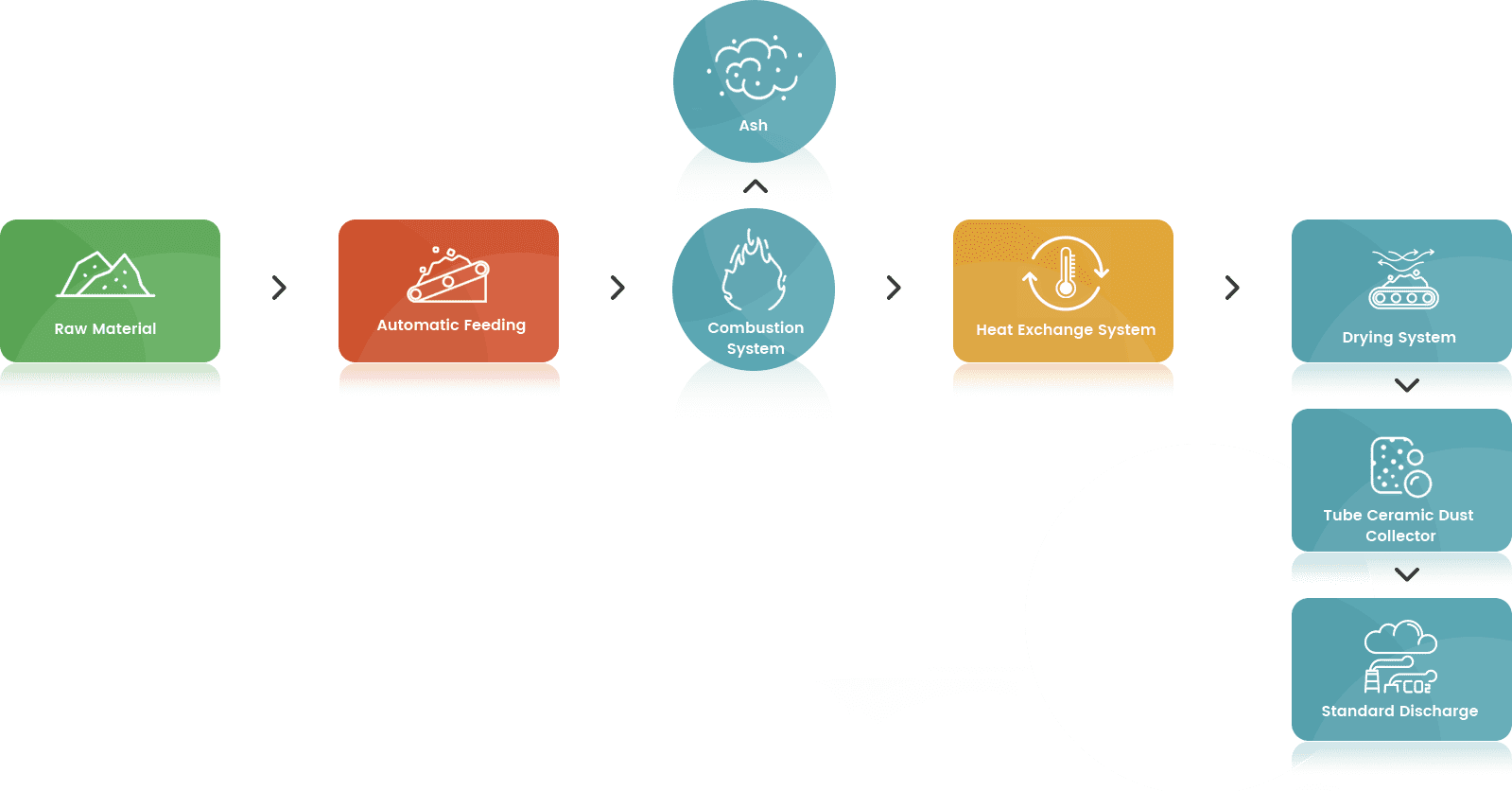

System Diagram

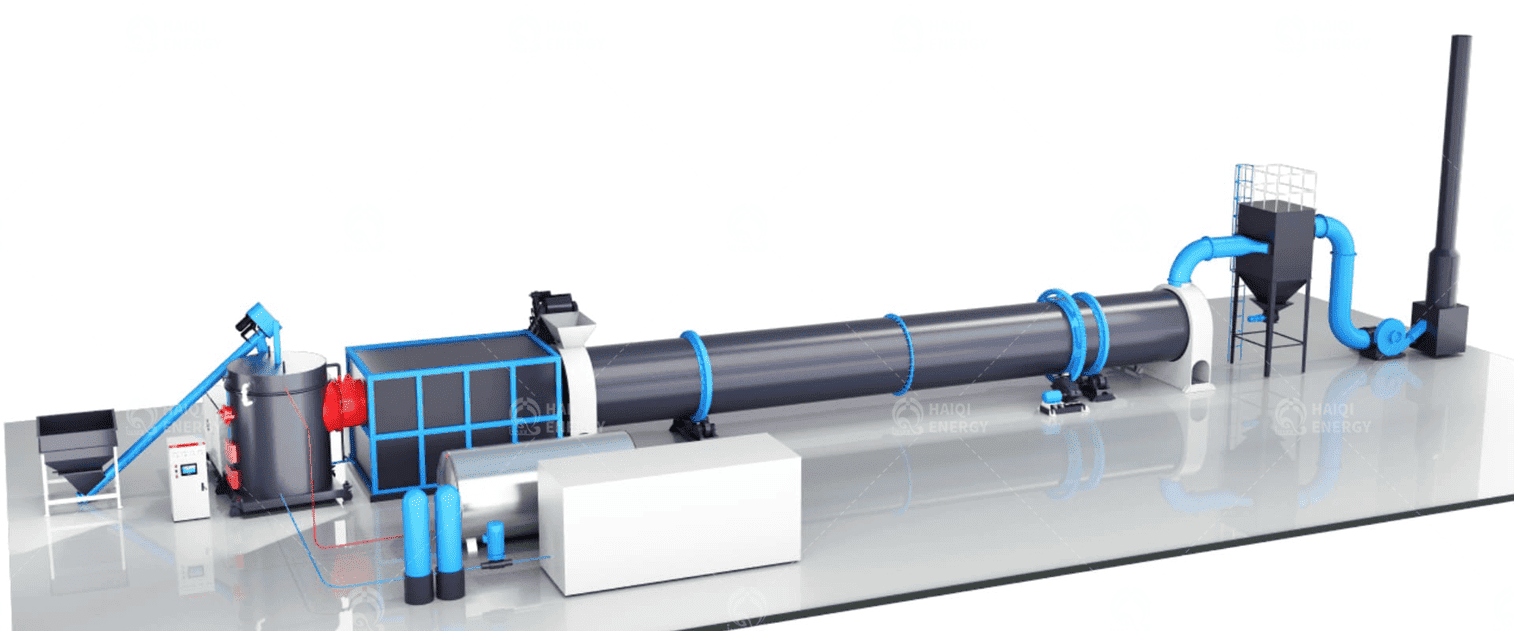

Biomass Pellet Burner Docking Boiler System

1. Screw Feeder

2. Biomass Pellet Burner

3. Control Cabinet

4. Heat Exchanger

5. Dryer

6. Multi-Tube Ceramic Dust Collector

7. Induced Fan

8. Chimney

9. Softened Water Device

10. Hot Water Tank

11. Cold Water Tank

1

Screw Feeder

2

Biomass Pellet Burner

3

Control Cabinet

4

Heat Exchanger

5

Dryer

6

Multi-Tube Ceramic Dust Collector

7

Induced Fan

8

Chimney

9

Softened Water Device

10

Hot Water Tank

11

Cold Water Tank

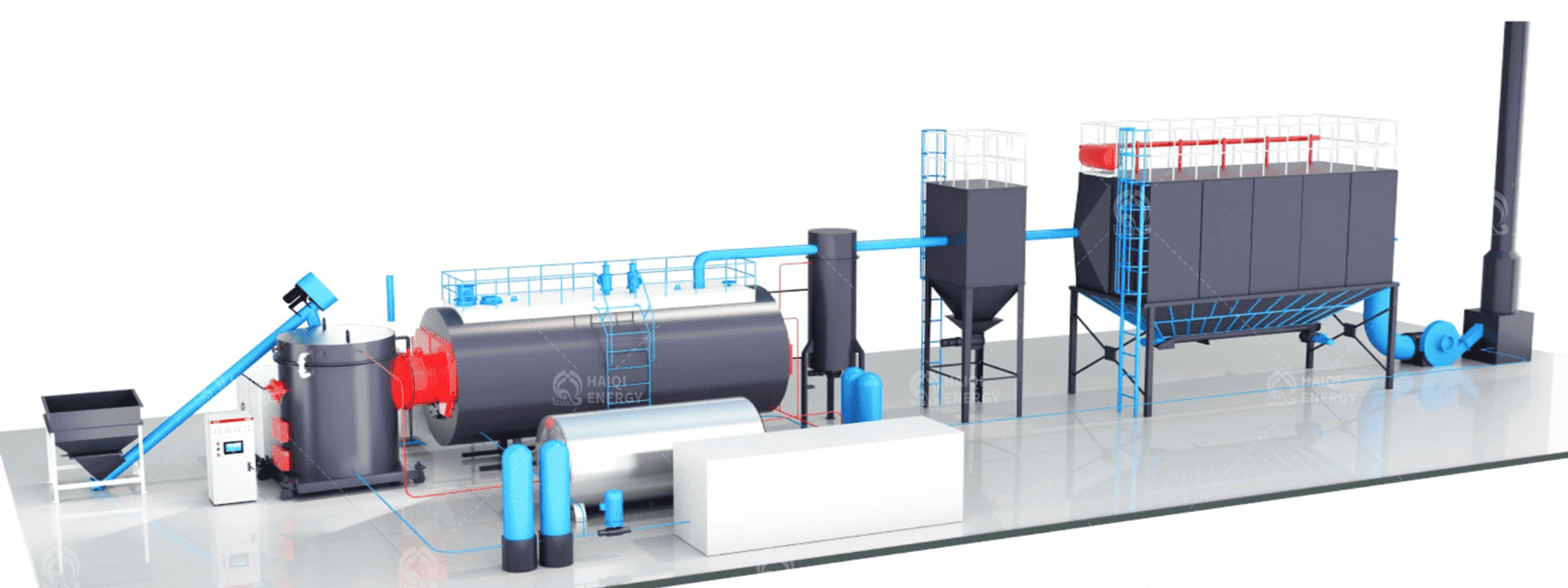

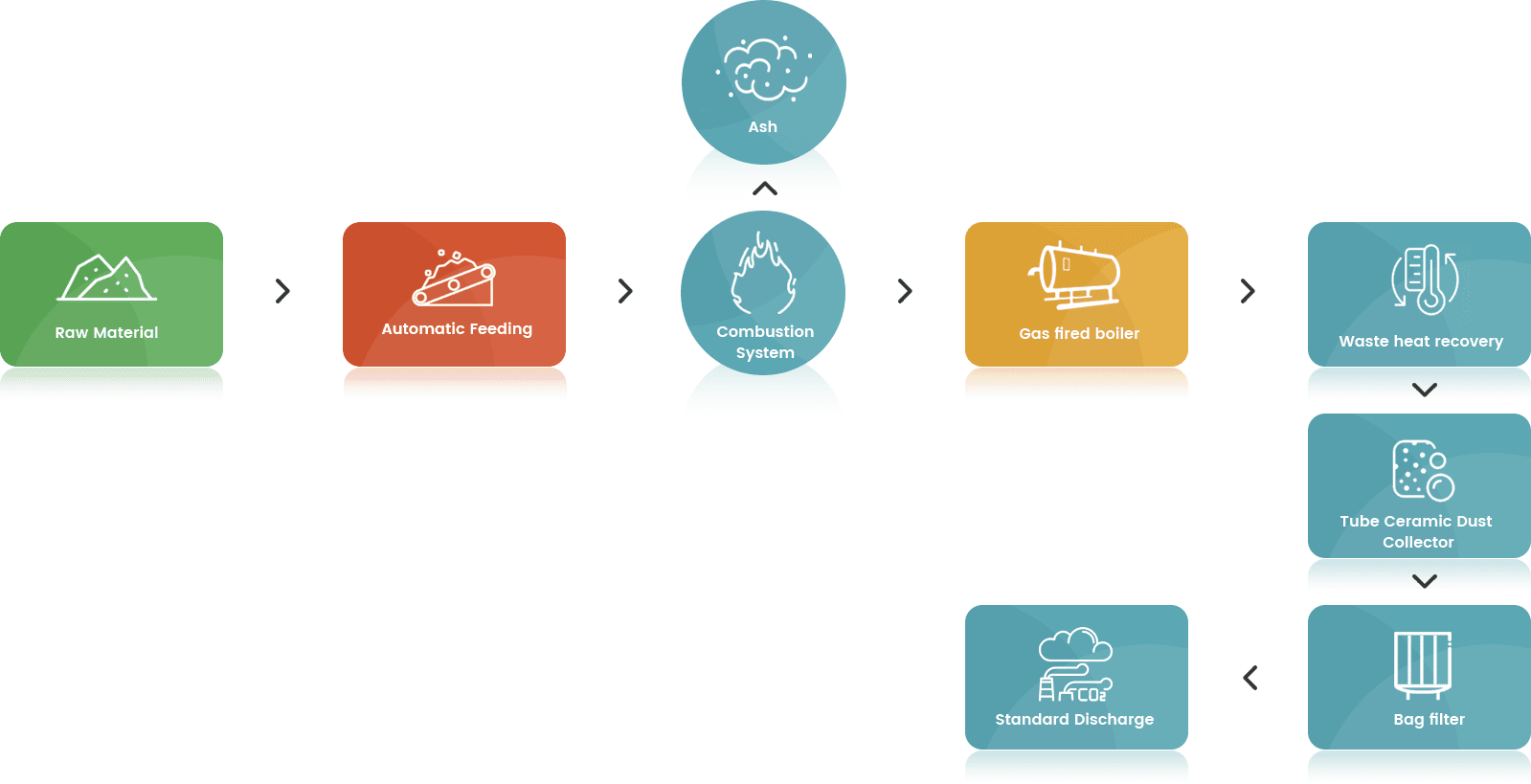

1. Screw Feeder

2. Biomass Pellet Burner

3. Control Cabinet

4. Oil Gas Boiler

5. Waste Heat Recovery

6. Multi-Tube Ceramic Dust Collector

7. Bag Filter

8. Induced Fan

9. Chimney

10. Softened Water Device

11. Cold Water Tank

12. Hot Water Tank

1

Screw Feeder

2

Biomass Pellet Burner

3

Control Cabinet

4

Oil Gas Boiler

5

Waste Heat Recovery

6

Multi-Tube Ceramic Dust Collector

7

Bag Filter

8

Induced Fan

9

Chimney

10

Softened Water Device

11

Cold Water Tank

12

Hot Water Tank

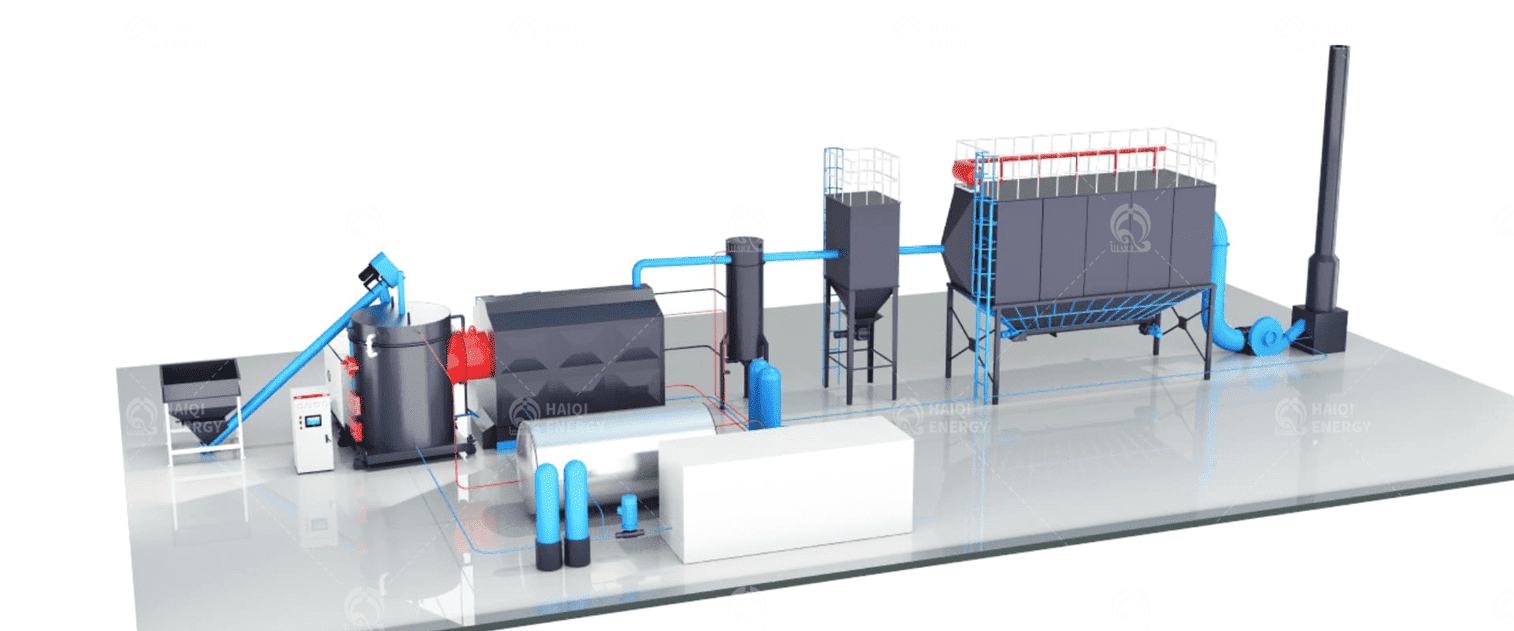

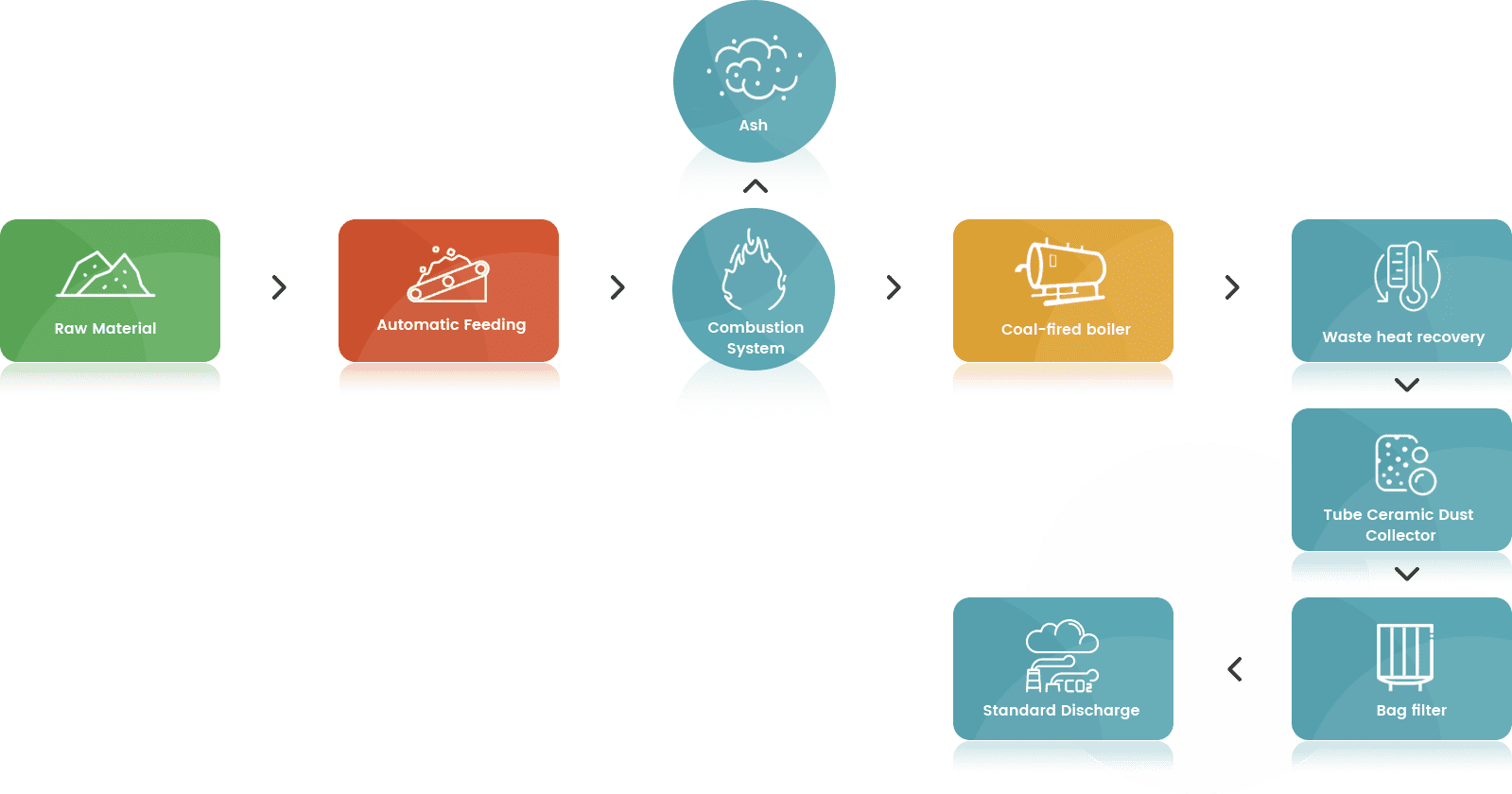

1. Screw Feeder

2. Biomass Pellet Burner

3. Control Cabinet

4. Coal-Fired Boiler

5. Waste Heat Recovery

6. Multi-Tube Ceramic Dust Collector

7. Bag Filter

8. Induced Fan

9. Chimney

10. Softened Water Device

11. Cold Water Tank

12. Hot Water Tank

1

Screw Feeder

2

Biomass Pellet Burner

3

Control Cabinet

4

Coal-Fired Boiler

5

Waste Heat Recovery

6

Multi-Tube Ceramic Dust Collector

7

Bag Filter

8

Induced Fan

9

Chimney

10

Softened Water Device

11

Cold Water Tank

12

Hot Water Tank

.jpg)

(1).jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)