What is a Biomass Combined Heat and Power Plant?

Definition of Combined Heat and Power (CHP)

Combined Heat and Power (CHP), also known as combined heat and power, is an efficient energy system that can generate both electricity and usable heat in the same process. In traditional power generation, most of the energy is lost as waste heat, while CHP systems use this part of the heat for heating, industrial processes or cooling through heat recovery mechanisms, significantly improving energy efficiency. Typically, the overall efficiency of CHP systems can reach 80%-90%, far exceeding the 40%-50% efficiency of traditional power generation systems.

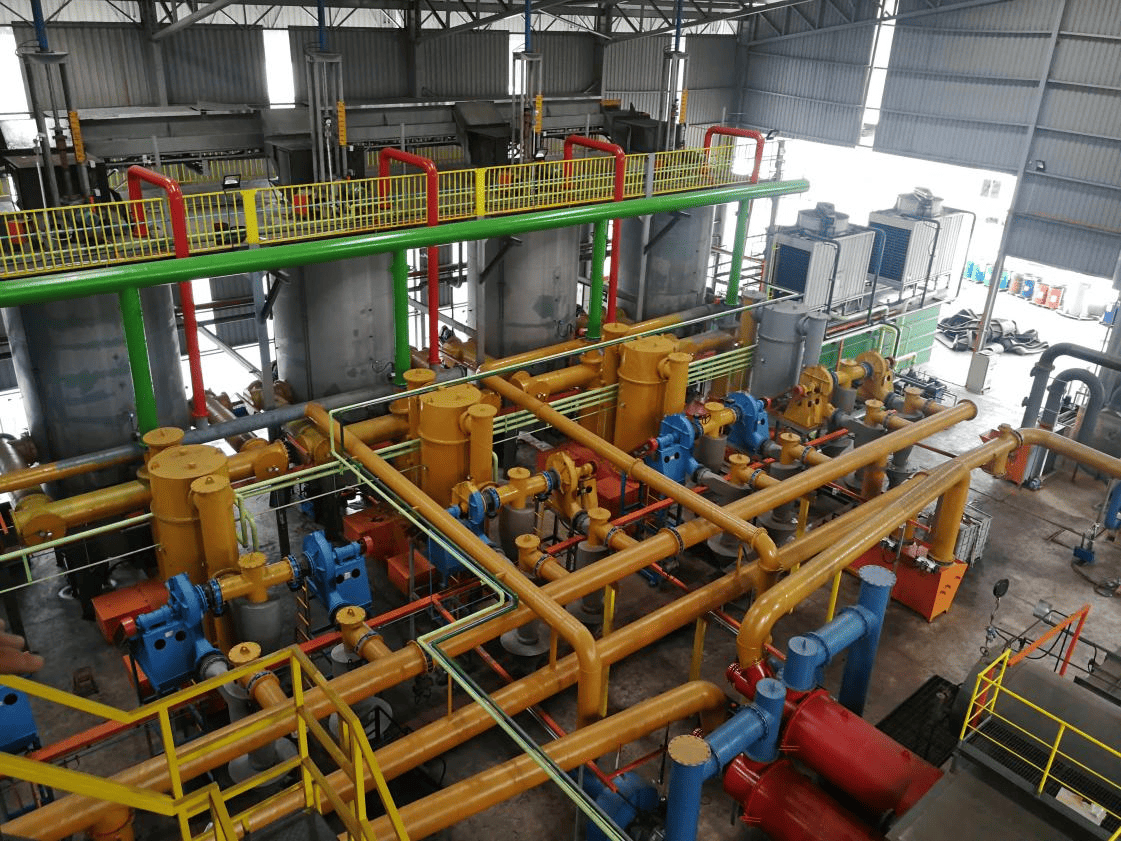

(Image source: HaiQi Biomass Gasification Cogeneration Project in Malaysia)

Compared with traditional CHP systems that rely on fossil fuels such as natural gas, coal or diesel, biomass combined heat and power plants use renewable organic matter such as agricultural waste, forestry by-products and animal waste as fuel. These organic wastes are converted into heat and electricity through thermochemical or biochemical processes.

The CO2 released during the combustion or gasification of biomass fuels has been absorbed by plants during the growth of raw materials, thus achieving carbon balance. Furthermore, if supplemented with carbon capture and storage (CCS) or the production of biochar, true negative carbon emissions can be achieved, providing a realistic path to achieve the net zero emission target.

Types of Biomass Cogeneration Technology

Traditional Biomass Combustion - Steam Turbine

This is the most widely used biomass CHP technology. Its working principle is to burn biomass to produce high-temperature and high-pressure steam, which drives the turbine to generate electricity, and then the waste heat of the steam is used for regional heating or industrial heating through the heat exchange system.It's suitable for large-scale centralized CHP projects (1MW and above), especially for urban heating systems or industrial users with large heat consumption. Due to its mature technology and a large number of successful cases around the world, this technology can be compatible with existing coal-fired facilities. However, its system is large, occupies a large area, and has high investment and maintenance costs.

Biomass Gasification - Internal Combustion Engine

Biomass gasification refers to heating solid biomass under oxygen-deficient conditions to convert it into a combustible gas (synthesis gas) rich in carbon monoxide and hydrogen, and then using the synthesis gas to drive an internal combustion engine or micro gas turbine to generate electricity, while recovering the waste heat generated by the engine.Biomass gasification power plant is suitable for distributed small and medium-sized CHP systems (100kW to 5MW), and has advantages in remote areas or agricultural clusters. Its system is modular, flexible in deployment, and has a wide range of fuel adaptability, suitable for a variety of raw materials such as rice husks, straw, and wood chips. But at the same time, it has high requirements for gas purification, complex tar treatment, high system integration, and high technical requirements for operation and maintenance personnel.

Organic Rankine Cycle (ORC)

ORC technology uses the medium and low temperature heat source generated by biomass to drive turbines to generate electricity by evaporating organic working fluids with lower boiling points (such as isobutane or heptane). This method does not require a traditional high-pressure steam system and is suitable for CHP projects where the thermal energy is not enough to generate high-temperature steam.ORC is well suited to a variety of CHP projects, such as farms, industrial parks, and energy centers. The ORC system is compact, adaptable, almost fully automatic, and relatively simple to maintain. However, the power generation efficiency of this technology is slightly lower than that of traditional high-temperature systems, and the initial investment cost is still not low.

How Biomass Cogeneration Plant Works: Taking Wood Gasification as an Example

Fuel Sources and Pretreatment

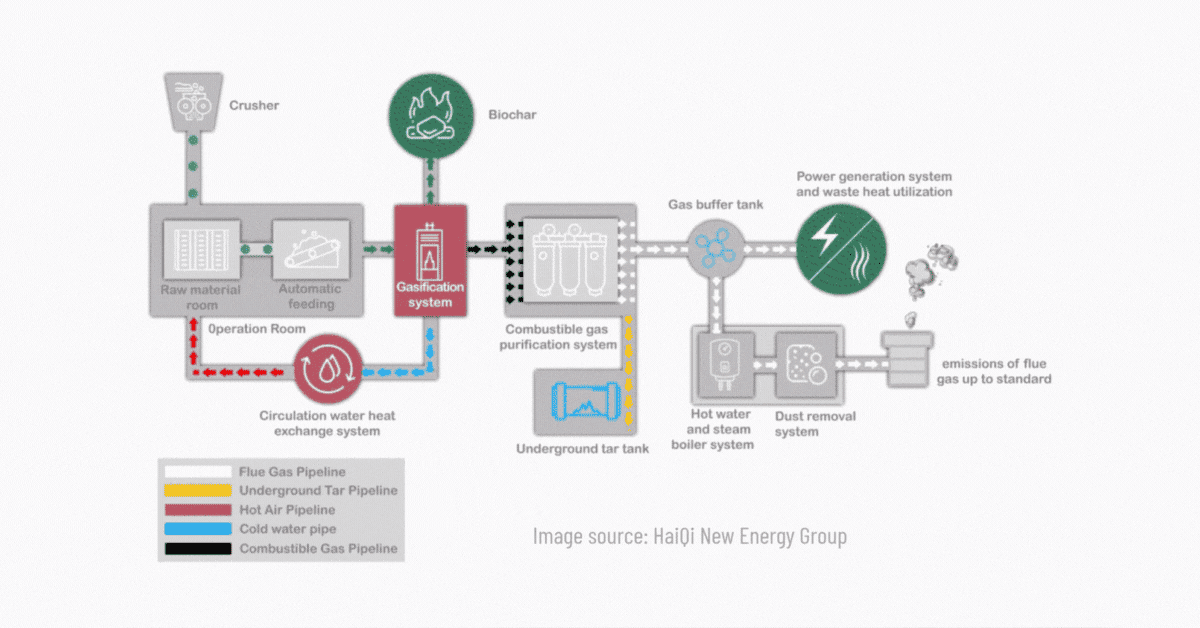

Biomass cogeneration plants can use a variety of wood fuels, such as forestry residues, furniture factory waste, and construction waste wood. Before entering the biomass gasifier, these raw materials are usually crushed, dried to a suitable moisture content, and compressed into pellets or uniform wood chips to ensure a stable gasification process.Gasification Process

The pretreated biomass enters the gasifier and is pyrolyzed in a high temperature and oxygen-deficient environment at around 800°C to generate combustible synthesis gas (syngas), whose main components are CO, H2, CH4, and a small amount of tar, water vapor and particulate matter.Gas Purification and Power Generation

The raw syngas produced by gasification must be decoked, filtered and cooled to avoid damaging the internal combustion engine. The purified gas enters the gas engine as fuel to drive the generator to produce electricity.Heat Recovery and Utilization

During the gasification, gas purification and internal combustion engine operation, a large amount of waste heat is released. The cogeneration system converts this part of heat into hot water or steam through a heat exchanger for:- District heating (heat network)

- Industrial steam process

- Absorption refrigeration to cool data centers or buildings

Application Scenarios of Biomass Cogeneration Plant

The biomass CHP system is very suitable for industries and regions with intensive energy consumption. For example:- Industrial enterprises such as papermaking, food processing, and chemicals

- Farms, livestock farms, and rural energy centers

- Urban heating systems

- Data centers that require cooling loads

Through the local use of power generation and heat energy, enterprises not only reduce energy costs, but also apply for carbon credits or grid subsidies, achieving a win-win situation for economy and environmental protection.

Advantages of Biomass Cogeneration Plant

Renewable Fuel Sources

The material sources are wide, including agricultural straw, forestry residues, food processing waste, etc. These resources have a short renewal cycle and are naturally renewable, which helps to build a low-carbon circular energy structure.

Low or Negative Emissions

The carbon emissions of biomass during combustion or gasification are much lower than fossil energy such as coal and natural gas. If combined with technologies such as biochar production and biomass carbon capture and storage (BECCS), it even has the potential to achieve negative carbon emissions, which is crucial to achieving carbon neutrality goals.Organic Waste-to-Energy

Biomass CHP promotes the efficient recycling of resources. By treating organic waste as energy, it significantly reduces the pressure of landfill and environmental pollution, and provides a feasible path for agricultural and urban waste management.Energy Structure Optimization

In terms of energy security, biomass is mostly obtained locally, so that the system operation can get rid of dependence on external energy imports and enhance regional energy independence.CCHP Solution

Biomass CHP can also provide multi-energy integrated services. It can not only be used for power generation, but also its waste heat can meet the needs of heating, hot water, and even absorption cooling. It is particularly suitable for distributed energy systems and combined heat, power and cooling scenarios. This one-stop energy service capability not only improves energy utilization efficiency, but also meets diverse terminal energy needs.Biomass Gasification Project Spotlight: Kohler Group's CHP Plant in Germany

In March 2025, Kohler Group officially announced that the combined heat and power (CHP) power plant in Oberkirch, Germany, had completed the transition from coal to biomass fuel, and held an inauguration ceremony on March 14. The project lasted two years and invested more than 70 million euros, marking an important step for the company in sustainable energy production. On June 10, 2024, the power plant burned the last batch of coal, and then began commissioning and trial operation of biomass fuel. On August 20, 2024, the boiler was ignited for the first time using biomass, and on August 30, the steam turbine and generator were successfully connected to the grid. The entire system was officially approved by the German Technical Supervision Association (TÜV) in early 2025.

The power plant uses circulating fluidized bed combustion technology, with an annual power generation of approximately 105,000 MWh and approximately 300,000 tons of process steam per year. By using locally sourced biomass fuels such as wood chips, green waste and papermaking residues, it is expected to reduce fossil carbon dioxide emissions by approximately 150,000 tons per year, providing strong support for achieving low-carbon industrial production.

With the increasing pressure of climate change, energy price fluctuations, and the gradual maturity of biomass resource development, biomass cogeneration, as one of the key technologies for clean energy transformation, is showing great potential. HaiQi has been committed to the field of biomass energy for nearly 30 years and can provide a series of biomass-based energy solutions, like cogeneration, biochar production, syngas production, etc. If you are interested in the detailed information of these solutions, please feel free to contact and discuss with us!

RELATED Blog