Biochar in the VCM: A New Path to CDR

VCM and CDR: The Basics

VCM (Voluntary Carbon Market) is a market where companies, economies, and groups voluntarily purchase carbon credits to offset their own carbon emissions. The corresponding market is the compliance market. In the compliance market, entities participate in the carbon market to meet regulatory requirements. For example, in a cap-and-trade system, entities may only be allowed to produce a certain level of emissions; if their emissions exceed the limit, they may need to pay a tax on the excess, or they may choose to offset it by purchasing carbon offsets.CDR technologies refer to Carbon Dioxide Removal technologies, also known as "carbon removal technologies" or "carbon dioxide removal technologies". Their goal is to directly remove and store CO2 in the atmosphere to combat climate change, beyond traditional emission reduction measures. CDR is a core means in the "net zero" path.

Currently, CDR technologies registered in VCM include Bioenergy Carbon Capture and Storage (BECCS), Direct Air Capture (DAC), Biochar, Enhanced Weathering (ERW), etc. Among them, biochar is considered to have the potential for steady growth due to its low cost, mature technology and sound standards.

Biochar: A Tool for Achieving CDR

Biochar is solid carbon formed by heating biomass waste (such as agricultural waste, forestry residues, etc.) in an oxygen-free environment. The production process of biochar is called pyrolysis, which converts organic biomass into carbon-rich substances that can be used as soil conditioners or carbon sequestration.

Biochar Production Process

Raw Material Preparation

Collecting and preparing biomass for pyrolysis. Taking Puro earth's methodological requirements as an example, the raw materials used for biochar production must be sustainable biomass, and the source process must comply with international standards such as forest management and agricultural sustainability. If the raw materials come from forests, they need to comply with sustainable forestry management. If the raw materials come from crop residues, it should be proven that they will not cause land degradation and soil fertility decline. In addition, Puro earth does not encourage the use of food crops for energy or biochar production unless it is proven that it will not affect food security.

Biomass Pyrolysis

The prepared biomass is heated to a high temperature in the absence of oxygen. After reaching a certain temperature, the biomass is carbonized. The pyrolysis process can be carried out in different types of equipment, such as rotary kilns or pyrolysis reactors. Depending on the technology used, the temperature, heating rate and residence time of the biomass in the pyrolysis reactor can be controlled to produce biochar with different properties.

Biochar Collection and Cooling

The temperature of the newly produced biochar is very high. If it is not cooled in time, it is extremely easy to condense naturally after contact with the air. Therefore, advanced biochar production equipment often cools the high-temperature biochar in an oxygen-free biochar conveying system.

Collection and Utilization of Pyrolysis By-products

In the process of biomass pyrolysis, in addition to the main biochar, pyrolysis gas, wood vinegar and wood tar are also produced. Puro earth methodology requires that pyrolysis gas must be recovered or utilized. At present, advanced pyrolysis technology usually uses pyrolysis gas for the self-heating process of the pyrolysis furnace. Some advanced pyrolysis equipment manufacturers also use pyrolysis gas and waste heat to produce green electricity to maximize resource utilization.

Advanced Biochar Production Equipment

In accordance with the EBC Guidelines for Sustainable Biochar Production, Verra clearly divides biochar production equipment into the high-tech and the low-tech. The following are the standards for high-tech equipment:Gas recovery or combustion: Greenhouse gases produced during pyrolysis must be recovered or burned and cannot be directly discharged into the atmosphere.

Thermal energy utilization requirements: The heat generated during pyrolysis must be utilized at least 70% (taking into account heat transfer efficiency).

Pollution control: The facility must be equipped with effective emission control equipment (such as thermal oxidizers, flue gas purification systems) and comply with local or international emission limit standards.

Process temperature monitoring: The temperature must be continuously measured and recorded during the production process.

If any of the above four items is not met, the facility is classified as a low-tech facility.

Application of Biochar

Soil Amendment

The loose and porous structure of biochar can improve the internal structure of soil, increase soil water holding capacity and soil permeability, reduce soil water evaporation, improve acidic soil, effectively adsorb heavy metals and organic pollutants in soil, and reduce pesticide residues.Animal Feed Additive

Biochar can be used as an additive for livestock and poultry feeds to improve the digestion and absorption of animal feeds, to promote growth, and to reduce the absorption of harmful substances in food by animals.Carbon Sequestration

Biomass is converted into biochar, which allows carbon elements that are easily released into the atmosphere to be fixed in the biochar, effectively achieving carbon sequestration. Studies prove that adding biochar to soil can sequester carbon dioxide for thousands of years. There is no doubt that biochar is one of the effective ways to slow down climate change.End Use of Biochar and CDR Applicability

| End Use of Biochar | Eligible for CDR? | Why? |

| Soil amendment (agriculture/landscaping) | ✅ Yes | Biochar remains stable in soil for centuries, enabling long-term carbon sequestration that meets CDR criteria. |

| Building materials (e.g., concrete) | ✅ Yes | Biochar is stably stored in construction materials, with carbon retention lasting decades to centuries, qualifying as CDR. |

| Animal feed additive | ✅ Yes | Biochar reduces methane from ruminants, contributing to CDR. |

| Combustion for energy (used as fuel) | ❌ No | Burning biochar releases carbon as CO2, which negates its carbon sequestration potential. |

| Metallurgical reductant | ❌ No | When used in metal smelting, biochar reacts and converts to CO2, failing to achieve effective carbon sequestration. |

Biochar in the Voluntary Carbon Market

So far, biochar is the only CDR technology that has been officially registered and issued carbon credits in Verra. Puro earth has more CDR technologies registered successfully, but biochar has the highest popularity among them due to its mature technology and lower delivery risk, and is still showing a steady growth trend. Major buyers such as Microsoft and Shopify have purchased biochar carbon credits on a large scale to fulfill their carbon reduction obligations.

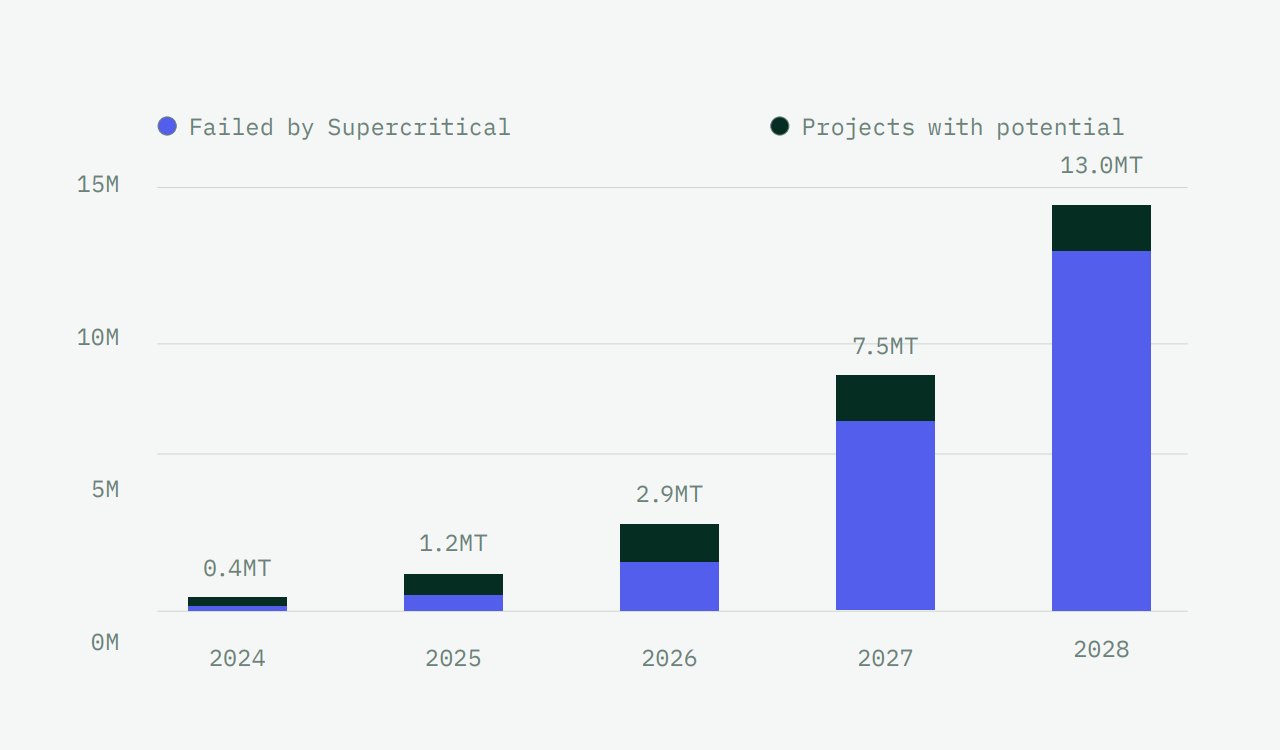

(Data Source: Supercritical Report)

Although the global biochar carbon removal market is expanding rapidly, biochar projects that meet high quality standards are still scarce resources. According to Supercritical's own data assessment, only 13% of carbon credits from biochar projects that did not pass its rigorous review in 2024 and 2025 were eventually sold successfully; in contrast, the sales rate of high-quality projects that passed the review was as high as 62%.Although the total global biochar carbon removal capacity is expected to increase to 2.9 million tons by 2026, about 70% of them are low-quality projects that cannot pass Supercritical's quality review. This means that although the number of high-quality carbon removal projects is small, they have become the object of market competition due to their higher credibility and sales performance. Once the purchase agreement is signed in advance, the resources of high-quality biochar projects left for other buyers will become increasingly limited, which also indicates that the price of high-quality carbon removal credits may rise in the future.

As a pyrolysis technology provider approved by Puro earth, HaiQi is opening up a new path in the carbon market. HaiQi supports biochar projects of all sizes by providing technical expertise, project cooperation and carbon credit services, aiming to deliver high-quality biochar production projects to project developers. If you are interested in developing a biochar CDR project, collaborating with HaiQi, or learning more about biochar BCR certification, please contact us immediately. We will provide you with professional support and customized solutions to help achieve carbon removal.

RELATED Blog

.jpg)