Batch and Continuous Biochar Production: Key Differences

Global interest in biochar production has grown significantly in recent years. From agricultural residues to forestry byproducts, biomass waste holds immense value creation potential. However, not all biochar production methods are created equal. Batch and continuous biochar production are currently the most widely used technologies, each with its unique operational characteristics, advantages, and limitations. Understanding these differences is crucial for investing in biochar projects.

What is Batch Biochar Production?

Batch biochar production is a traditional method of biochar production. It is a cyclical process involving loading, pyrolysis, cooling, and unloading. This method is typically suitable for small-scale operations and projects handling mixed biomass feedstocks.Loading and Sealing Cycle

In a batch pyrolysis system, operators feed a fixed amount of feedstock into the reactor. Once full, the reactor is sealed to create an anaerobic environment, allowing for controlled pyrolysis. The sealed reactor ensures effective heat retention, enabling the biomass to undergo thermal conversion to produce biochar and byproducts.Pyrolysis and Cooling

After sealing, the pyrolysis reactor is heated to the required pyrolysis temperature, typically between 400°C and 700°C, depending on the type of feedstock and the characteristics of the biochar required. During this stage, biomass decomposes, releasing syngas and forming carbon-rich biochar. After the reaction is complete, the reactor must be cooled for safe product extraction. The cooling phase can be time-consuming, often consuming a significant portion of downtime during batch operation.Unloading and Reset

After cooling, biochar and other byproducts are discharged from the pyrolysis reactor manually or semi-automatically. After the unload process, any remaining ash or non-combustible materials need to be removed, which also prepares the reactor for the next batch of pyrolysis. Typically, batch biochar plants can only operate for a few production cycles per day, limiting their total output. While batch production units offer flexibility and robustness with a variety of feedstocks, their batch nature results in lower efficiency in the large-scale biochar production.What is Continuous Biochar Production?

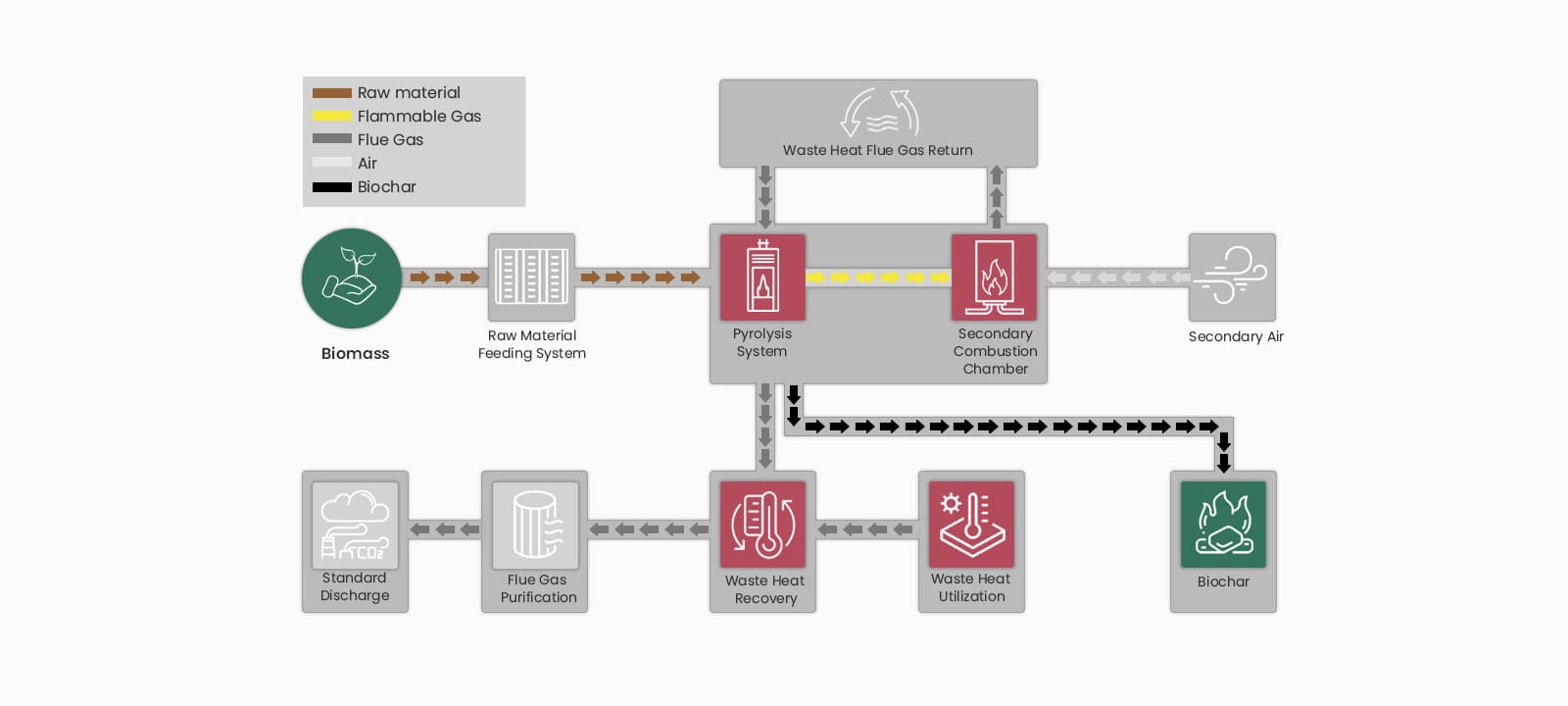

In contrast, continuous biochar production uses an automated, uninterrupted process to convert biomass into biochar, syngas, and pyrolysis oil. This method is designed for industrial-scale production and excels in efficiency, consistency, and energy recovery.

Continuous Feeding System

Continuous pyrolysis units utilize automated feeding systems (e.g., screw conveyors) to deliver pre-treated feedstock into the pyrolysis furnace. The size and moisture of the feedstock must be consistent to avoid blockages and ensure smooth operation. This requirement makes continuous systems more suitable for processing standardized biomass feedstocks such as sawdust and biomass pellets.Stable Operation

Unlike batch reactors with frequent start-stop cycles, continuous systems maintain a stable high-temperature environment. The pyrolysis process can continue continuously from the biomass inlet to the outlet. This stable operation avoids downtime and ensures the consistency of biochar quality. The continuous flow of feedstock also facilitates precise control of residence time, temperature, and reaction conditions, resulting in consistent biochar.Simultaneous Product Extraction

One of the key advantages of continuous pyrolysis units is the ability to extract pyrolysis products in real time. Biochar, pyrolysis oil, and non-condensable gases can be collected and extracted simultaneously at different locations within the system, while the syngas generated during pyrolysis can be used to heat the pyrolysis reactor, enabling self-sustaining operation of the biochar equipment. This energy recovery significantly improves thermal efficiency and reduces the overall energy consumption of the equipment.Key Differences Between Batch and Continuous Biochar Production

Feeding Requirements

Batch systems are more tolerant of variations in raw materials. They can handle non-uniform materials such as irregular branches, mixed agricultural residues, etc. However, continuous systems require pretreatment of raw materials to achieve a uniform level to ensure a continuous supply. Maintaining consistent raw material size and moisture content prevents clogging and helps improve production efficiency.Processing Capacity

Batch biochar production methods are suitable for small to medium-sized projects, typically processing 12-16 tons of biomass per day. In contrast, continuous systems are better suited for large-scale biochar production. Since continuous pyrolysis units can operate continuously around the clock, they can even process more than 100 tons of biomass per day. For large projects, continuous systems offer significant advantages in maximizing output and meeting commercial needs.Manual & Automation

The nature of batch pyrolysis processes requires significant human intervention, including loading, unloading, and restarting, all of which require manual participation. In contrast, continuous systems offer greater automation, reducing labor costs, but they require more advanced pyrolysis technology. Automated production also ensures consistent biochar quality and minimizes the probability of human error.Energy Efficiency

Energy efficiency is another key difference. Batch systems require repeated heating and cooling of the reactor, leading to energy loss. Continuous systems maintain a constant high-temperature environment and recycle syngas as fuel, achieving self-sufficiency and thus higher thermal efficiency, while reducing operating costs and environmental impact.

Choosing the Right Biochar Production Equipment for Your Project

Before selecting the biochar production technology, you need to clearly define your project goals and resource conditions, and conduct a comprehensive assessment of raw materials, scale, capital investment, and long-term operational objectives.Processing Capacity

Continuous biomass pyrolysis systems offer significant advantages for companies processing large volumes of biomass waste. Their 24/7 operation ensures stable and large-scale biochar production. However, smaller projects may not require such high processing capacity. Batch pyrolysis technology offers flexibility and lower initial investment, making it suitable for pilot projects or companies processing multiple biomass sources.Characteristics of the feedstock

Feed characteristics play a crucial role in determining the appropriate pyrolysis technology. Continuous systems are suitable for standardized feedstocks, while batch systems are better suited for processing various and irregular feedstocks. For projects processing mixed agricultural waste, batch reactors allow operators to adjust processing conditions for each batch, ensuring optimal biochar quality.Operating Costs

Continuous pyrolysis units typically require higher upfront investment due to the complexity of automation, feedstock pre-treatment systems, and integrated energy recovery. However, reduced labor costs and improved energy efficiency can lower long-term operating costs. Batch units have lower initial construction and equipment investment costs, but manual operation and repetitive heating cycles can lead to higher unit costs.Sustainability Goals

Both batch and continuous pyrolysis contribute to reducing carbon emissions and achieving sustainable waste management. Continuous systems offer higher energy efficiency and syngas recovery rates, resulting in greater environmental benefits per tonne of biomass processed. While batch systems are less energy efficient, they allow for smaller operators in biochar carbon sequestration projects, making them more suitable for community projects and smallholder farmers.With the increasing intensity of climate action, biochar is having a significant impact on the global carbon removal market. If you are considering developing an industrial-scale biochar production project, please feel free to contact HaiQi. Our own advanced continuous biomass pyrolysis system has been vetted by the leading global carbon removal platform and can convert various biomass wastes into high-quality biochar and durable carbon credits. From technology implementation to carbon revenue realization, HaiQi provides you with a one-stop carbon removal solution!

.png)

.jpg)