From Biomass Waste to Carbon Credits: High-Quality Biochar Projects Explained

As the demand for durable carbon removal continues to grow, biochar has emerged as one of the most scalable and scientifically validated solutions in the industry. However, building a truly high-quality biochar carbon removal project is far more complex than simply installing a pyrolysis system. It requires a rigorous, full-lifecycle management framework to establish credibility in the carbon market and gain recognition.

A comprehensive assessment of annual feedstock availability, collection radius, and logistics costs is essential. For instance, confirm whether the annual output of straw within your collection radius can support long-term project operation. Establish a standardized storage system to keep feedstock moisture content below 20%, reducing energy consumption and costs during the pyrolysis process.

If feedstock must be procured externally, sign long-term supply agreements to minimize risks associated with feedstock price fluctuations and shortages.

When choosing a site, locate the biochar production facility close to both the feedstock source and biochar application areas (such as farmland or plantations) to reduce transportation-related emissions. The site must also comply with environmental regulations, avoiding residential or water protection zones, and include early planning for wastewater and exhaust gas treatment systems in line with local land use and environmental policies.

Conduct a full life-cycle cost analysis, covering feedstock collection, equipment procurement, operation, and maintenance. Combine this with projected revenue streams from biochar sales, carbon credit income, and waste management fees to determine the expected return on investment (ROI). To enhance investor confidence, consider insurance coverage against risks like natural disasters or equipment malfunction, ensuring financial stability and project resilience.

Select the right pyrolysis technology and biochar pyrolysis equipment. At the heart of the project lies the high-temperature, oxygen-limited pyrolysis process, which converts biomass into stable biochar capable of storing carbon for hundreds of years.

During production, closely monitor key parameters such as temperature and residence time to ensure the biochar's H/Corg ratio meets high-stability standards, preventing premature carbon release.

If used for soil enhancement, adjust the application rate and method according to soil type, and document the application site, area, and timing.

If used for industrial applications, ensure stable and long-term storage conditions.

Implement a biochar quality control system, testing for potentially harmful substances such as polycyclic aromatic hydrocarbons (PAHs), and comply with standards such as the European Biochar Certificate (EBC) to ensure environmental safety and project integrity.

Other standards, such as Verra, can also be referenced depending on the project type. Review the relevant methodologies in advance to ensure your project's workflow aligns with certification requirements.

Engage third-party auditors for regular verification to ensure data transparency and traceability, providing a solid foundation for certification.

Once sufficient operational data is collected, undergo third-party verification to obtain certified carbon credits — such as CORCs issued by Puro.earth.

Currently, biochar carbon credits are trading at around USD 160 per ton, offering strong financial returns.

Biochar itself can be sold as a soil amendment to farmers and plantation operators or used in industrial adsorption applications, creating diversified revenue streams.

Reinvest a portion of the profits into equipment maintenance and technological upgrades to ensure long-term operational sustainability.

Stay informed of policy and certification updates — such as the EU CRCF and GCD frameworks — and adjust project processes accordingly.

If you've read this far and are ready to take the first step toward developing your own biochar carbon removal project, HaiQi is here to support you — not just as a technology provider, but as a long-term partner in building a credible, revenue-generating carbon removal business.

We invite you to share your project idea with our team. Once we receive your ideas, our engineers will evaluate your feedstock, expected capacity, and regional conditions, and then recommend the most suitable biomass pyrolysis equipment for your needs.

From there, we can help you design a complete project road map — covering pre-feasibility analysis, energy recovery integration, MRV preparation, and connections with trusted carbon credit certification partners such as Puro.earth.

If you're planning multiple projects or considering large-scale deployment, HaiQi can provide customized engineering, modular biomass pyrolysis plant, and ongoing technical support to ensure operational stability and compliance with the latest international standards. You can simply contact us through our website to start the conversation. Together, we'll bring your project online — transforming waste biomass into valuable, high-stability biochar that meets global carbon removal standards, while helping your organization generate verified carbon credits and long-term environmental impact.

Ensure Sustainable and Traceable Biomass Feedstock

Feedstock is the core of any biochar carbon removal project. Priority should be given to uncontested waste biomass such as agricultural residues, forestry by-products, and nut shells — avoiding any materials that could affect food security or ecological balance.A comprehensive assessment of annual feedstock availability, collection radius, and logistics costs is essential. For instance, confirm whether the annual output of straw within your collection radius can support long-term project operation. Establish a standardized storage system to keep feedstock moisture content below 20%, reducing energy consumption and costs during the pyrolysis process.

If feedstock must be procured externally, sign long-term supply agreements to minimize risks associated with feedstock price fluctuations and shortages.

Define Clear Project Objectives

Begin by clarifying the core purpose of your project — whether the focus is on carbon credit generation, biochar sales, or a combination of soil enhancement and carbon removal. The project scale and design should align with these goals.When choosing a site, locate the biochar production facility close to both the feedstock source and biochar application areas (such as farmland or plantations) to reduce transportation-related emissions. The site must also comply with environmental regulations, avoiding residential or water protection zones, and include early planning for wastewater and exhaust gas treatment systems in line with local land use and environmental policies.

Develop a Credible Financial Model

A sound financial framework integrates multiple funding sources — such as government green subsidies, venture capital, and green bonds — and can also adopt hybrid financing models.Conduct a full life-cycle cost analysis, covering feedstock collection, equipment procurement, operation, and maintenance. Combine this with projected revenue streams from biochar sales, carbon credit income, and waste management fees to determine the expected return on investment (ROI). To enhance investor confidence, consider insurance coverage against risks like natural disasters or equipment malfunction, ensuring financial stability and project resilience.

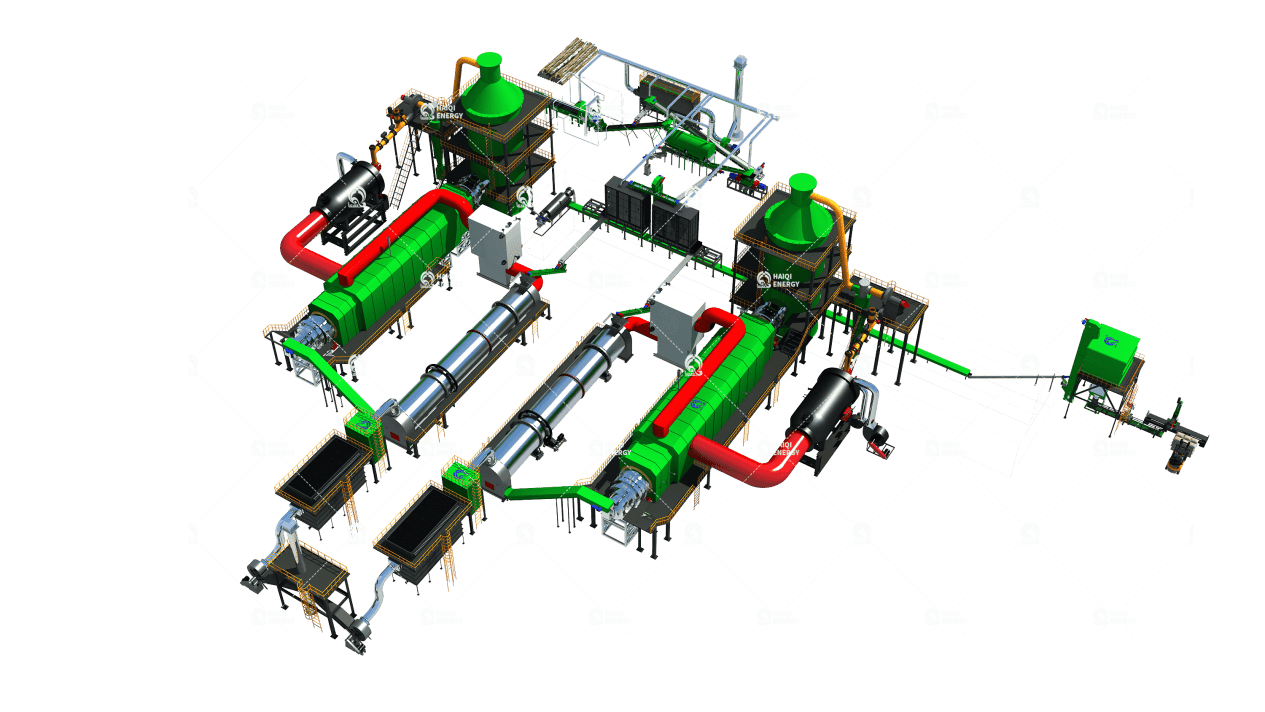

Implement Biochar Production and Carbonization Quality Control

Select the right pyrolysis technology and biochar pyrolysis equipment. At the heart of the project lies the high-temperature, oxygen-limited pyrolysis process, which converts biomass into stable biochar capable of storing carbon for hundreds of years.

Choose a technically proven carbonization system, such as HaiQi's CNBC series biomass pyrolysis plant — approved by Puro.earth — which also recovers syngas generated during pyrolysis for heat and power, improving overall energy efficiency.

During production, closely monitor key parameters such as temperature and residence time to ensure the biochar's H/Corg ratio meets high-stability standards, preventing premature carbon release.

Develop a Standardized Biochar Application Plan

The end-use of biochar directly determines the permanence of carbon sequestration.If used for soil enhancement, adjust the application rate and method according to soil type, and document the application site, area, and timing.

If used for industrial applications, ensure stable and long-term storage conditions.

Implement a biochar quality control system, testing for potentially harmful substances such as polycyclic aromatic hydrocarbons (PAHs), and comply with standards such as the European Biochar Certificate (EBC) to ensure environmental safety and project integrity.

Certification: Obtaining Recognized Carbon Credit Accreditation

Select a High-Standard Certification Framework

Choose globally recognized carbon removal certification bodies — the most widely adopted for biochar projects being Puro.earth, known for its rigorous century-scale permanence criteria. Puro issues CORCs (Carbon Removal Certificates), which are highly valued in voluntary carbon markets.Other standards, such as Verra, can also be referenced depending on the project type. Review the relevant methodologies in advance to ensure your project's workflow aligns with certification requirements.

Establish a Full MRV (Monitoring, Reporting, and Verification) System

MRV is the backbone of carbon credit certification. Equip your biochar project with digital monitoring systems to track the full carbon flow — from feedstock input to biochar production and end-use application. Record data such as feedstock carbon content, biochar yield, and carbon sequestration efficiency.Engage third-party auditors for regular verification to ensure data transparency and traceability, providing a solid foundation for certification.

Complete Project Registration and Credit Issuance

Submit Project Design Documents (PDDs) to the chosen certification platform, including feedstock assessments, technical descriptions, and MRV plans. After successful review, register your project.Once sufficient operational data is collected, undergo third-party verification to obtain certified carbon credits — such as CORCs issued by Puro.earth.

Ensure Project Sustainability and Value Realization

Monetize Carbon Credits and Biochar Products

For carbon credits, establish long-term purchase agreements with major companies that have sustained carbon removal needs — such as Microsoft or Google — or with carbon credit brokers.Currently, biochar carbon credits are trading at around USD 160 per ton, offering strong financial returns.

Biochar itself can be sold as a soil amendment to farmers and plantation operators or used in industrial adsorption applications, creating diversified revenue streams.

Reinvest a portion of the profits into equipment maintenance and technological upgrades to ensure long-term operational sustainability.

Maintain Compliance and Continuous Optimization

Ensure continuous compliance with environmental regulations and perform regular maintenance of carbonization equipment and monitoring systems to maintain high sequestration efficiency and accurate reporting.Stay informed of policy and certification updates — such as the EU CRCF and GCD frameworks — and adjust project processes accordingly.

Additionally, conduct impact assessments to document improvements in soil fertility or crop yields. Establish long-term partnerships with local communities and farmers, publicly disclose environmental impact reports, and maintain open communication to strengthen transparency, trust, and project credibility.

If you've read this far and are ready to take the first step toward developing your own biochar carbon removal project, HaiQi is here to support you — not just as a technology provider, but as a long-term partner in building a credible, revenue-generating carbon removal business.

We invite you to share your project idea with our team. Once we receive your ideas, our engineers will evaluate your feedstock, expected capacity, and regional conditions, and then recommend the most suitable biomass pyrolysis equipment for your needs.

From there, we can help you design a complete project road map — covering pre-feasibility analysis, energy recovery integration, MRV preparation, and connections with trusted carbon credit certification partners such as Puro.earth.

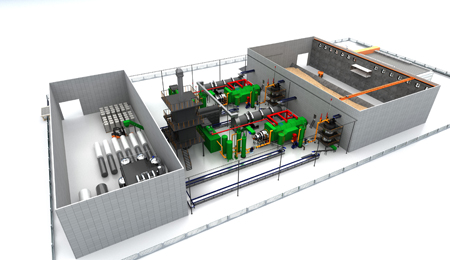

If you're planning multiple projects or considering large-scale deployment, HaiQi can provide customized engineering, modular biomass pyrolysis plant, and ongoing technical support to ensure operational stability and compliance with the latest international standards. You can simply contact us through our website to start the conversation. Together, we'll bring your project online — transforming waste biomass into valuable, high-stability biochar that meets global carbon removal standards, while helping your organization generate verified carbon credits and long-term environmental impact.

RELATED Blog