Biochar Production: An Effective Carbon Removal Solution

Biochar has garnered significant global interest as a scalable climate solution, primarily due to its strong carbon storage potential and a range of agricultural and ecological co-benefits. Since 2019, the voluntary carbon market has expanded rapidly, accelerating biochar deployment. By June 2025, large corporations and nonprofits had collectively purchased over 2.7 million tonnes of CO₂equivalent in voluntary carbon credits from more than 80 biochar suppliers worldwide.

Beyond its role in carbon removal, biochar application in soil offers numerous benefits, including improved water and nutrient retention, balanced soil pH, and pollution remediation. In agricultural and pasture systems, enhanced soil quality fosters healthier plant growth, contributing to food security and sustainability. Additionally, biochar supports rural economic development and contributes to the circular economy, making it a truly sustainable climate solution.

The primary function of biochar is to lock away carbon that was originally absorbed from the atmosphere during photosynthesis. In the absence of intervention, most plant-based carbon would eventually decompose, returning to the atmosphere as CO₂. Pyrolysis interrupts this natural carbon cycle by converting a portion of the biomass carbon into stable, long-lasting forms that resist degradation for centuries.

Biochar sits at the intersection of carbon removal, soil restoration, and sustainable development. With the right production technologies and certification standards, biochar can deliver durable, verifiable, and high-efficiency carbon sequestration — while enhancing agricultural resilience and supporting rural communities. If you are considering developing a biochar production project for carbon removal, HaiQi is your trusted partner. In collaboration with Puro earth, we help project developers worldwide achieve end-to-end success-from biochar production equipment manufacturing to project development, carbon credit registration, and trading. Through continuous research and investment in biochar production technologies, we can realize the full potential of biochar as a climate solution and pave the way toward a more sustainable future.

Beyond its role in carbon removal, biochar application in soil offers numerous benefits, including improved water and nutrient retention, balanced soil pH, and pollution remediation. In agricultural and pasture systems, enhanced soil quality fosters healthier plant growth, contributing to food security and sustainability. Additionally, biochar supports rural economic development and contributes to the circular economy, making it a truly sustainable climate solution.

What is Biochar and How is It Produced?

Biochar is a carbon-rich solid material created through the pyrolysis of biomass, a process that involves heating organic materials in a low-oxygen environment. The feedstocks used for biochar production are diverse and may include:- Agricultural residues (such as nut shell, straw, and sugarcane bagasse)

- Forestry waste (wood chips, bark, and sawdust)

- Organic waste (food scraps, yard waste, and manure)

- Construction debris (wood-based materials)

- Marine biomass (like seaweed)

The primary function of biochar is to lock away carbon that was originally absorbed from the atmosphere during photosynthesis. In the absence of intervention, most plant-based carbon would eventually decompose, returning to the atmosphere as CO₂. Pyrolysis interrupts this natural carbon cycle by converting a portion of the biomass carbon into stable, long-lasting forms that resist degradation for centuries.

Main Methods of Biochar Production

Pit Kilns

Pit kilns are one of the most basic biochar production methods and are widely used by smallholder farmers. In this approach, biomass is burned in trenches covered with soil to create a low-oxygen environment. While this method is inexpensive and easy to implement—requiring minimal technology or infrastructure—it often leads to significant air pollution, releasing particulate matter and volatile organic compounds (VOCs). Furthermore, the carbon yield from pit kilns is typically lower than that achieved with more controlled biochar production systems, which limits their overall climate benefit.Kon-Tiki Kilns

The Kon-Tiki kiln represents a more efficient yet still low-tech alternative. Biomass is burned in an open conical kiln, where new material is continuously added during the process and the burn is quenched with water at the end. Compared to pit kilns, Kon-Tiki systems produce a higher yield of biochar and can handle larger biomass volumes. However, they still generate considerable emissions relative to industrial-scale biochar production technologies and require skilled management to maintain proper combustion and temperature control throughout the process.Industrial Biochar Pyrolysis Plant

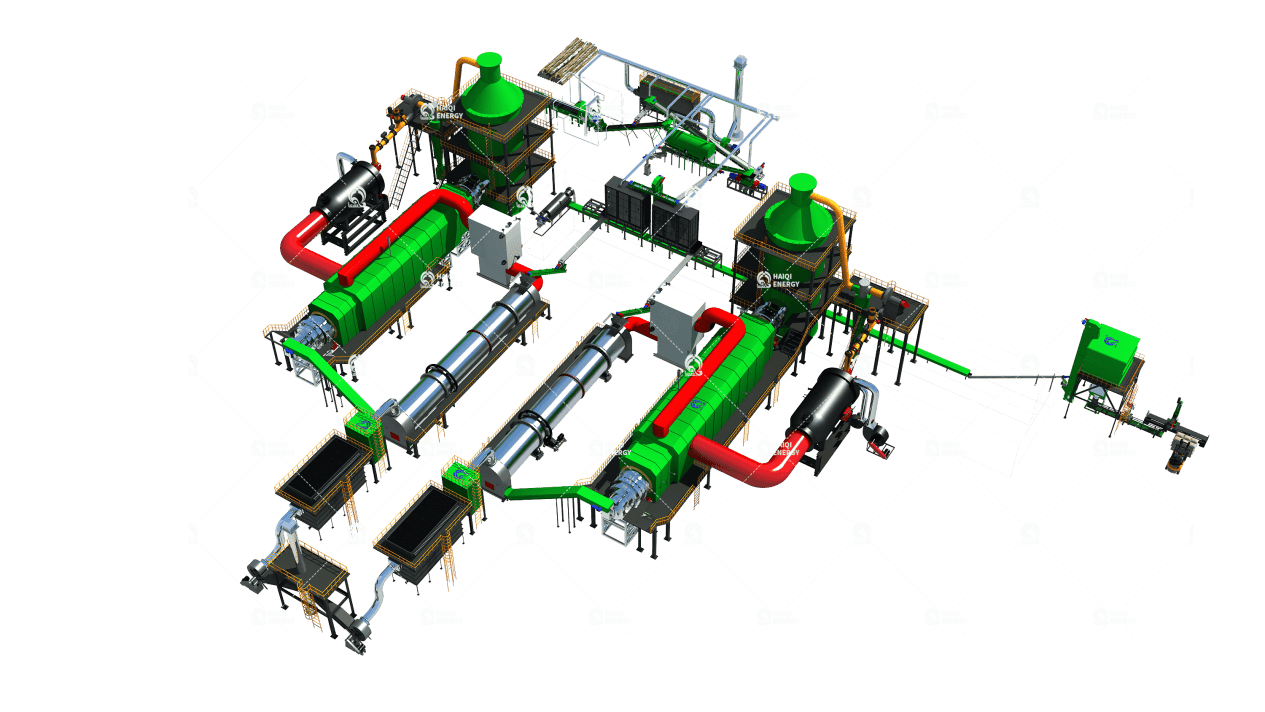

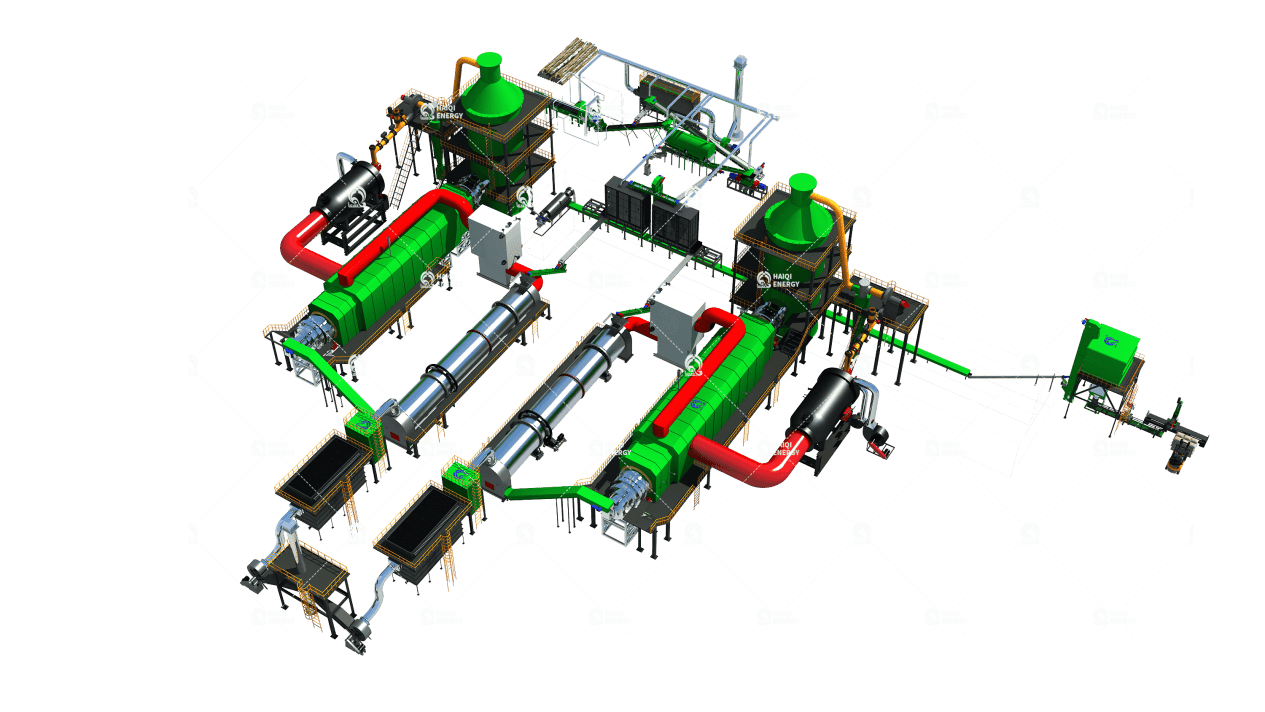

Industrial biomass pyrolysis plants heat biomass under precisely controlled, oxygen-free conditions to produce biochar and syngas. These systems are highly efficient, producing minimal emissions and biochar with superior stability—ideal for long-term carbon sequestration. Additionally, the syngas generated can be combusted to provide process heat, further improving energy efficiency and reducing fossil fuel use. Despite these advantages, industrial-scale biochar production equipment demands significant upfront investment and technical expertise, which can pose challenges for smaller producers.

Batch and Continuous Pyrolysis Systems

Pyrolysis technologies can be designed as batch or continuous systems. Batch systems process biomass in separate loads, making them easier to operate and suitable for small-scale production. Continuous systems, by contrast, feed biomass into the reactor without interruption, allowing for higher throughput, greater energy efficiency, and lower operational costs. However, continuous systems require more sophisticated infrastructure and control mechanisms to maintain stable operating conditions, while batch systems, though simpler, are less efficient and labor-intensive at larger scales.Biomass Gasification Plant

Gasification primarily targets energy generation, but it can also yield biochar as a byproduct. This process involves the partial combustion of biomass at high temperatures, resulting in the production of both syngas and biochar. The syngas can be used to generate electricity or heat, making biomass gasification an attractive option for combined energy and carbon management. Nevertheless, since the main focus is energy output, the resulting biochar may be of lower quality or produced in smaller quantities compared to dedicated pyrolysis systems.Advanced Technologies

Emerging biochar production methods such as microwave-assisted pyrolysis and torrefaction represent the forefront of technological innovation. These advanced processes are designed to increase energy efficiency, improve yield, and tailor biochar characteristics for specific applications such as soil enhancement. Although they hold great promise for high-performance, low-emission production, many of these technologies remain in the research or early commercialization stages, and their high initial costs continue to limit widespread adoption.Durability of Biochar Carbon Removal

Durability, or permanence, is a crucial metric in evaluating the climate effectiveness of biochar carbon removal (CDR). It refers to how long the carbon stored in biochar remains sequestered—often modeled over 100 years or more. Certification standards such as Puro.earth, Verra, and Carbon Standards International quantify durability using measurable chemical indicators. One of the most common is the hydrogen-to-organic-carbon ratio (H/Corg), which serves as a proxy for the biochar's molecular stability.

A lower H/Corg ratio generally indicates a more stable, long-lasting biochar, as it contains more condensed aromatic carbon structures that resist microbial decomposition. Biochar with an H/Corg ratio below 0.4 is considered highly stable, with research suggesting that under this threshold, 70% of the carbon will remain sequestered for at least 100 years.

Key Factors Affecting the Durability of Biochar

Feedstock Type of Biochar

The type of biomass used for biochar production significantly influences its stability. Woody biomass tends to produce more stable biochar than crop residues or manure due to its higher lignin content, which contributes to the aromatic structure and carbon stability.Pyrolysis Temperature

Higher pyrolysis temperatures (typically above 500°C) yield biochar with greater aromaticity and lower H/C ratios, both of which are key to long-term stability. While higher temperatures can reduce the yield of biochar, they enhance its durability, making it a trade-off that producers must consider.Soil Environment

The environmental conditions in which biochar is applied play a vital role in its longevity. Soil pH, moisture, microbial activity, and texture affect how biochar interacts with its surroundings. Alkaline and dry conditions tend to preserve biochar longer, while acidic or highly moist environments may lead to faster degradation.Application Method

The method of applying biochar to soil can also impact its durability. Deep incorporation into soil reduces exposure to oxygen and erosion, further extending biochar's effective carbon storage life. Surface application, while easier, may expose biochar to more microbial activity and erosion, potentially shortening its lifespan.Biochar sits at the intersection of carbon removal, soil restoration, and sustainable development. With the right production technologies and certification standards, biochar can deliver durable, verifiable, and high-efficiency carbon sequestration — while enhancing agricultural resilience and supporting rural communities. If you are considering developing a biochar production project for carbon removal, HaiQi is your trusted partner. In collaboration with Puro earth, we help project developers worldwide achieve end-to-end success-from biochar production equipment manufacturing to project development, carbon credit registration, and trading. Through continuous research and investment in biochar production technologies, we can realize the full potential of biochar as a climate solution and pave the way toward a more sustainable future.

Next Article:

1970-01-01