Guide to Choosing a Biochar Machine

In recent years, with the expansion of the voluntary carbon market, biochar has rapidly emerged as a globally recognized solution for carbon removal and soil improvement. Driven by the market's enthusiasm and the demand for stricter sustainable development goals, investment intentions in biochar production systems have been continuously increasing.

However, selecting the right biochar production equipment is no easy task. You need to choose suitable biochar equipment based on the comprehensive situation of your project. This article provides a guide to help investors, project developers, and enterprises make informed decisions when selecting the most appropriate biochar production equipment.

.png)

Clarify Your Application Goals

Before delving into the technical specifications or models of biochar equipment, it is crucial to clarify the main purpose of your biochar project. Generally, biochar equipment mainly serves three types of goals:Biochar-centered Applications

For projects with biochar production as the core goal, the focus is usually on soil improvement and carbon sequestration. Enterprises in the agricultural sector are particularly interested in biochar because it can enhance soil fertility, improve water retention, and increase crop yields. Moreover, if you aim to achieve carbon sequestration/carbon removal goals through biochar, your biochar equipment needs to comply with strict monitoring and verification protocols, such as advanced carbon credit certification platforms like Puro.earth or Verra. In this case, your biochar equipment should be optimized to ensure the consistency of biochar yield and quality.

Energy Production-centered Applications

In some projects, energy recovery is the primary goal. The biochar production process releases syngas (a mixture of hydrogen, carbon monoxide, and methane) and bio-oil as by-products. These by-products can be used for combined heat and power (CHP) or further refined for industrial use. If your project aims to reduce fossil fuel usage, a continuous biochar equipment with strong gas purification, energy integration, and continuous operation capabilities is your best choice.Integrated Applications

Some projects require both biochar production and energy generation. For example, distributed energy plants may use biomass residues for combined heat and power generation while producing biochar as a by-product. This win-win model is usually attractive to municipal authorities, eco-industrial parks, or agricultural cooperatives. For such projects, it is recommended to choose a hybrid or continuous pyrolysis system with flexible operation modes.Match Biochar Production Equipment Based on Raw Material

The type of raw material plays a decisive role in determining the suitability of biochar equipment. Biomass materials vary greatly in density, moisture content, ash composition, and calorific value, all of which affect equipment efficiency and product quality.Woody Biomass

Woody raw materials such as sawdust, wood chips, and waste pallets typically have high carbon content and relatively low ash content. Lignocellulosic raw materials are very suitable for traditional biomass pyrolysis systems. Machines designed for stable production capacity and moderate temperatures (approximately 500-600°C) usually handle these raw materials well.Nut Shells

Hard and dense biomass, such as nut shells and fruit pits, require higher operating temperatures for complete carbonization. Specialized high-temperature pyrolysis equipment (with temperatures up to 700-800°C) can ensure full decomposition and prevent incomplete carbonization.Sewage Sludge and Animal Manure

If your raw materials are municipal sludge or livestock manure, you need to be extra cautious. Due to odors and potential heavy metals or pollutants, the biochar machine must integrate advanced gas purification systems and pollutant capture technologies. In addition, you may need pre-drying solutions to optimize carbonization efficiency because of their high water content.Impact of Calorific Value and Moisture Content

Low-calorific-value raw materials require more external heat to maintain the pyrolysis reactor temperature, which may additionally increase operating costs. Moreover, high-moisture biomass requires extensive drying, which also affects efficiency. Therefore, for raw materials with uneven quality, choosing a biochar system with integrated drying is usually crucial.Compare Pyrolysis Equipment Types

Currently, there are different types of biochar machine designs available on the market to adapt to different biochar production scales and operational strategies.Batch Biochar Machines

Batch systems are relatively simple and affordable, suitable for small projects or pilot projects. However, their production capacity is limited, and downtime between cycles may reduce production efficiency.Continuous Biochar Machines

Continuous systems allow biomass to be fed into the reactor without interruption, ensuring stable biochar output and continuous energy recovery. Such systems have higher investment costs but are very suitable for commercial-scale projects. Their advantages include higher automation, better gas utilization, and reduced labor requirements.Mobile and Containerized Units

For projects in remote or dispersed areas, mobile or containerized biochar equipment can provide unparalleled flexibility. Mobile biochar systems can be deployed on-site to directly process biomass, reducing transportation costs, and are suitable for demonstration projects or decentralized waste management schemes.

Get a Quote Now

Evaluate Key Technical Parameters

When selecting biochar equipment, you should carefully examine its technical performance indicators.- Processing Capacity: Consider the output in tons per day. Mismatch between equipment processing capacity and biomass supply may lead to underutilization or supply shortages.

- Feeding Requirements: Moisture content, particle size, fluidity, etc. Different biochar equipment have different feed requirements.

- Heating Methods: Direct heating, indirect heating, etc.

- Operating Temperature: The equipment should be flexibly adjustable within the range of 400-1000°C according to raw materials and desired biochar characteristics.

- Product Output and Recovery: Biochar production yield, proportion of by-products (wood vinegar, wood tar), pyrolysis gas recovery, waste heat recovery, etc.

- Gas Purification and Emission Control: Configure a suitable gas purification system according to local environmental protection regulations to ensure that the exhaust emissions of the pyrolysis equipment meet environmental standards and gain community recognition.

- Energy Consumption and Self-sufficiency: Understand the consumption of different types of fuels required for the operation of the biochar pyrolysis equipment, and choose the best fuel based on local fuel prices. In addition, equipment that can recover pyrolysis gas and use it for internal heating of the pyrolysis reactor can reduce reliance on external fuels and improve cost-effectiveness.

Economic and Policy Considerations

In addition to technical factors, cost factors also play a decisive role in equipment selection.Investment and Operating Costs

Capital costs vary depending on equipment type and capacity. Batch systems may have lower initial investment costs but require more labor to maintain operation and have lower long-term efficiency. Although continuous systems have higher upfront costs, they can bring higher returns in large-scale operations. It is crucial to select suitable biochar production equipment according to your project scale and budget.Durability and Maintenance

Well-designed equipment should have a long service life, be easy to maintain, and have reliable technical support, but they often cost more. Frequent equipment shutdowns can quickly damage the profitability of the project. If you only seek short-term biochar production and have a limited budget, you may choose a lower-priced biochar equipment. However, regardless of whether you want to produce biochar for the long term or short term, selecting a reliable biochar equipment manufacturer is crucial.Carbon Credit Certification

If you want to earn carbon credits from your biochar project, your biochar equipment must ensure compliance with recognized standards, such as Puro.earth's CORC or Verra's methodologies. This requires equipment capable of producing verifiable characteristics (such as stable carbon content, ash percentage, porosity). Equipment equipped with big data monitoring systems can simplify certification audits and reduce risks. Companies or manufacturers that can provide both biochar equipment and carbon credit services are even better.HaiQi: Your Customized Biochar Production Solution Expert

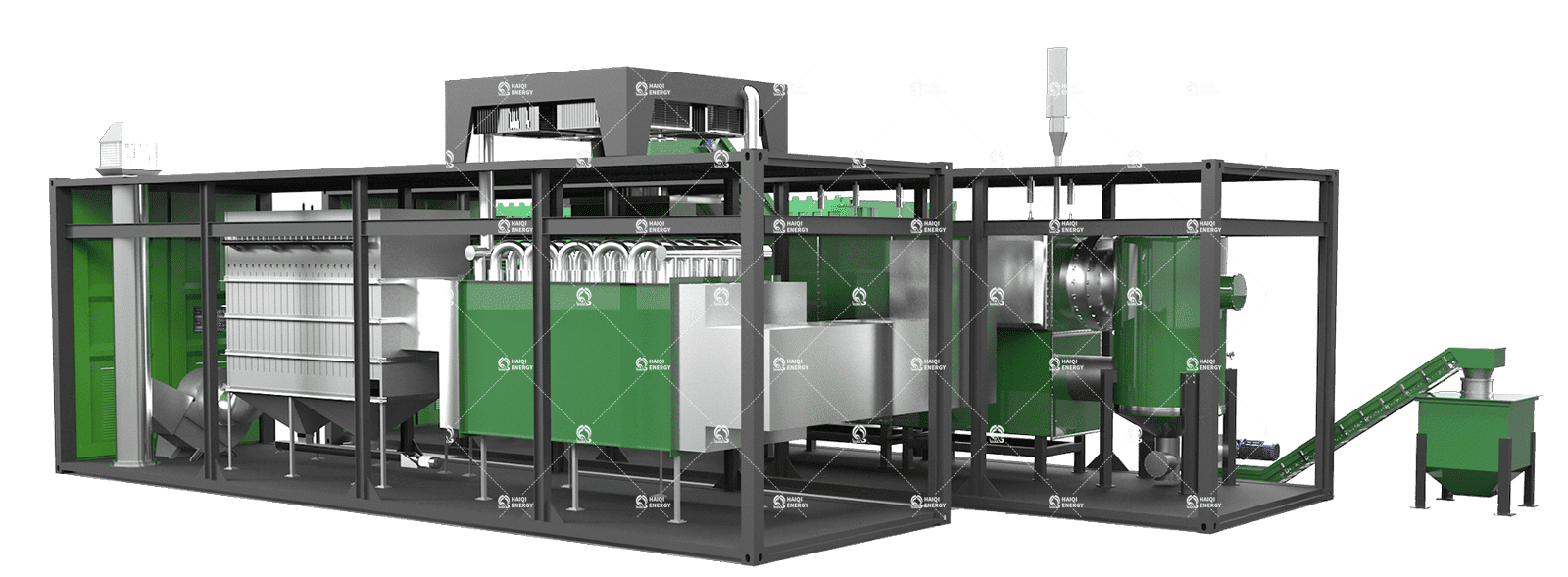

HaiQi New Energy Group, a biochar CDR technology partner of Puro.earth, specializes in designing and manufacturing a wide range of biochar production equipment, from mobile biochar units to medium- and large-scale stationary biomass pyrolysis plants. We transform diverse biomass wastes into biochar, carbon credits, and green electricity, delivering tailored biochar production solutions to meet the unique needs of your project.

Our advanced technical standards support your carbon removal journey —every unit is built with the highest requirements for efficient biochar yield, clean energy generation, and compliant emissions control. Contact us today, and let our professional technical team provide an in-depth project assessment and deliver full-cycle support — from equipment selection to the successful implementation of your project!

.jpg)

.jpg)