Biochar Carbon Credits: Key Facts

What are Biochar Carbon Credits?

Biochar is a highly stable, porous carbonaceous material produced by the high-temperature pyrolysis of biomass (such as wood, straw, nutshells, and livestock manure) under oxygen-deficient or oxygen-limited conditions. It resembles a sponge, but is harder and more stable. Unlike more common charcoal and activated carbon, its primary function is not to be used as a fuel or simply to filter impurities, but to help improve soil quality. In addition to conditioning soil, biochar is also an excellent carbon sequestration tool. When organic biomass is transferred into biochar, the carbon dioxide originally absorbed from the atmosphere by plants or trees through photosynthesis is converted into a stable, solid form. Biochar carbon credits quantify the biochar's ability to fix atmospheric carbon dioxide and are standardized, tradable environmental certificates..png)

Advantages of Biochar Credits Over Other CDRs

Long-term, Stable Carbon Sequestration

Scientific research has shown that biochar can sequester carbon for periods of up to one or even centuries, far exceeding other carbon sequestration solutions such as forest carbon sinks (30-100 years). The reason is that during the biochar production process, easily degradable components in organic matter, such as cellulose and hemicellulose, are broken down, leaving the remaining carbon in a stable aromatic ring structure, resulting in extremely stable carbon. Furthermore, unlike forest carbon sinks, which are susceptible to factors such as fire, pests and climate change, once biochar is formed and properly applied to the soil and other environments, its carbon sequestration status remains relatively stable, as long as it is not subject to large-scale human disturbance or extreme changes.Easy to Quantify

The carbon sequestration process of biochar has a relatively clear material basis and a reliable calculation method. Biochar is produced by the pyrolysis of biomass under anoxic conditions. Its carbon sequestration potential can be determined through certain experiments and calculations. For example, each ton of biochar can sequester 2.5-3 tons of CO₂, which is three times the carbon sequestration efficiency of forests. Furthermore, information involved in the biochar production process, such as the type of raw materials, technical parameters of the biochar production equipment, pyrolysis temperature, yield, and end use, can be recorded and monitored, facilitating audits by third-party certification agencies. Compared to some carbon sequestration methods (such as long-term carbon storage estimates from afforestation), the carbon sequestration of biochar is easier to quantify and track.

Multiple Benefits

In addition to environmental benefits, the biochar production process produces a variety of byproducts, such as bio-oil, heat, and combustible gas. These byproducts, when properly collected and utilized, can be converted into electricity, heat, or liquid fuel. Combustible gas can directly drive gas-fired generators, providing clean electricity for industry, agriculture, or data centers. The heat can be used for district heating, greenhouse heating, or industrial process heat, replacing fossil fuels and reducing additional carbon emissions. This process significantly reduces production costs while generating additional revenue for project developers.Biochar Carbon Credit Market Insights

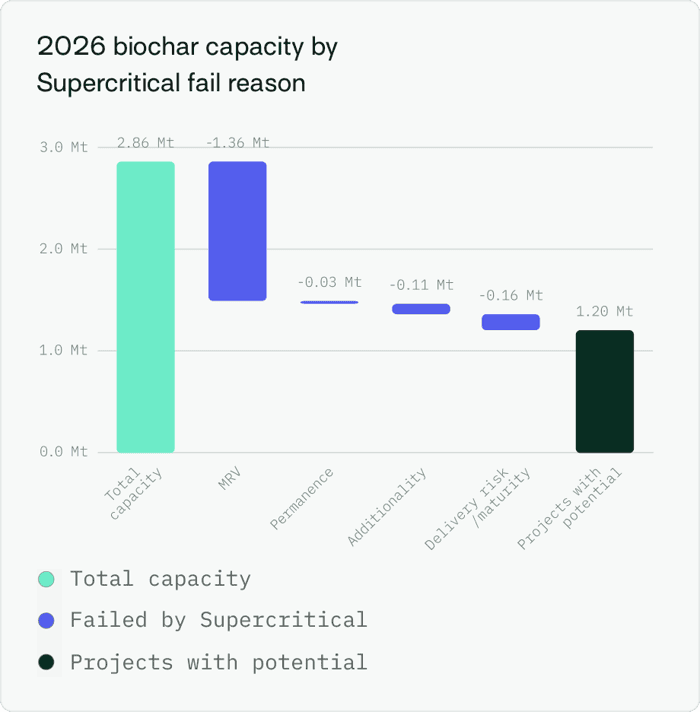

According to the CDR FYI data report over the past three years, biochar CDRs continue to maintain their leading position. In 2022, biochar held a strong position, accounting for 87% of all durable CDR deliveries, and in 2023, biochar CDR reached 92.9% of all durable CDR deliveries! Biochar also accounted for 86% of all deliveries in 2024. "We expect the ratio of biochar CDR deliveries to purchases to increase as early-stage development methods mature and their removal capabilities improve" (CDR.fyi 2024 Year of Review). However, it's worth noting that high-quality biochar CDRs remain scarce. Most high-quality biochar credits are locked in through offtake agreements, ensuring buyers secure a stable supply in the future and avoiding the risks of market shortages and price fluctuations.

(Source: Supercritical)

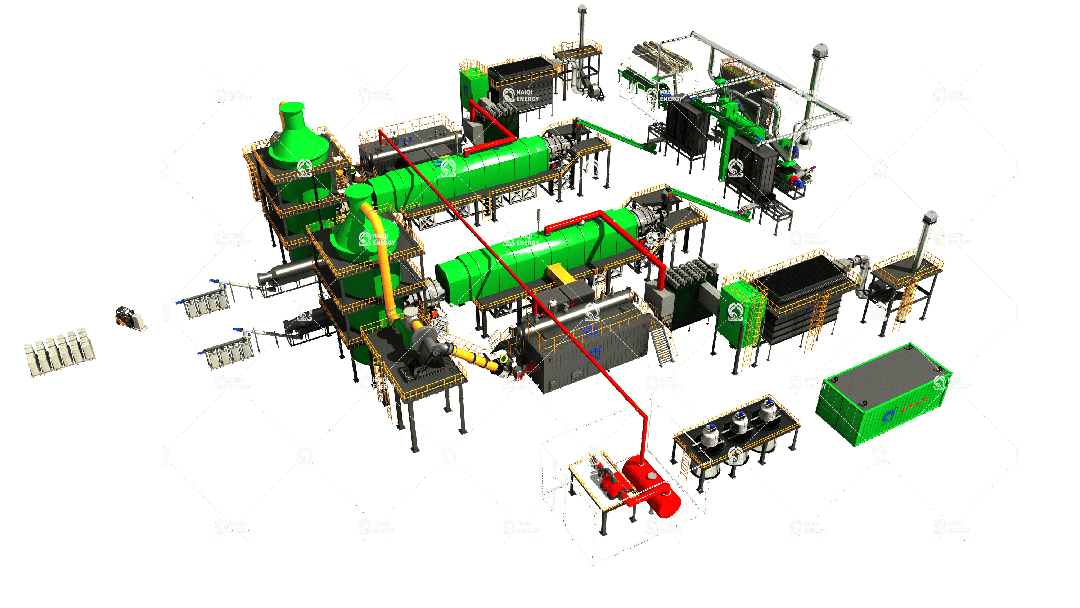

Compliance of Biochar Production Equipment

Not all biochar meets CDR requirements, which explains why high-quality biochar CDRs remain popular in the voluntary carbon market. According to the European Biochar Certificate (EBC), traditional smokeless pyrolysis systems, such as earthen kilns, do not meet sustainable production requirements. Modern, advanced biomass pyrolysis equipment improved energy efficiently and avoids environmental damage, and is therefore certified as compliant with the EBC standards. Verra's methodology directly references the EBC Guidelines for Sustainable Biochar Production, clarifying the requirements for high-tech biochar production equipment:(a) The pyrolysis gas produced during pyrolysis must be recovered or combusted—greenhouse gases are not allowed to escape into the atmosphere;

(b) At least 70 percent of the heat energy produced by pyrolysis must be used (taking into account heat transfer inefficiencies) to ensure that energy is recovered as well as biochar;

(c) Pollution controls such as a thermal oxidizer or other emissions controls are present that meet local, national, or international emission thresholds.

(d) The production temperature is measured and reported.

If any of these conditions are not met, the facility is categorized as a low-tech production facility.

Potential Risks in Biochar Credit Assessment

Feedstock Selection and Potential Leakage Risks

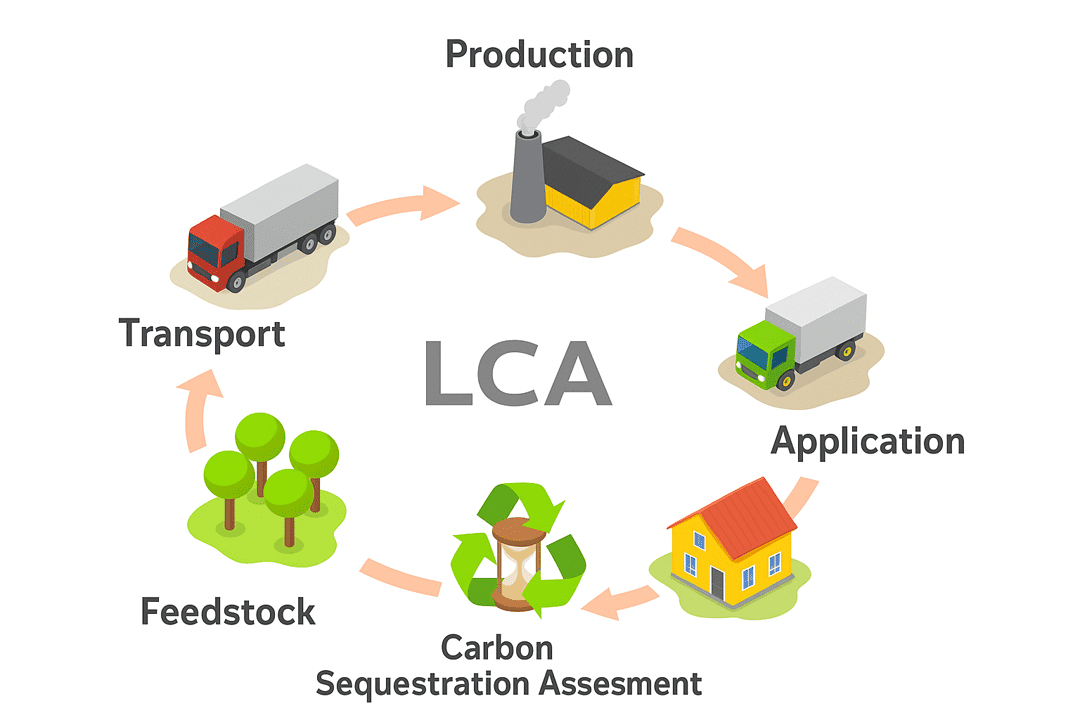

Some producers may use feedstock that is not certified or does not meet sustainability standards. Further complicating matters, they may divert biomass that could otherwise be used for emission reduction purposes to biochar production. For example, if a type of biomass could replace fossil fuels for power generation but is instead used to make charcoal, it may result in additional emissions in other processes, a situation known as "leakage."Life Cycle Assessment (LCA) Completeness

The emission reduction effects of biochar need to be examined throughout its entire life cycle. For example, relying on diesel vehicles for raw material transportation will increase greenhouse gas emissions, thereby weakening its overall climate benefits. Therefore, when evaluating projects, investors must examine whether a systematic and transparent life cycle assessment has been conducted.Biochar Production Process and Stability

The stability of biochar is closely related to the raw material and process. Generally speaking, biochar made from wood waste tends to be more stable than biochar made from agricultural residues and has lower reversal risks. Furthermore, industrial biochar production equipment has higher conversion efficiency and carbon sequestration potential than manual methods, which are also important factors in evaluating the quality of biochar CDR projects.Tracking Biochar End Use

The application scenario of biochar directly affects its durability. For example, biochar incorporated into building materials can achieve long-term carbon sequestration, while direct application to farmland requires regular assessment of its retention. Therefore, institutions purchasing carbon credits should pay particular attention to the actual use and relevant data of biochar.In summary, before investing in a biochar carbon credit project, you should focus on transparency in the raw material source, a complete life cycle analysis, and the scientific evidence supporting the long-term stability of the biochar. Only by ensuring these key aspects are verified can the environmental value of the investment be truly reliable. In today's rapidly developing carbon removal market, choosing a reliable and efficient production path is particularly important. Only by utilizing high-tech biochar production equipment and strict compliance standards can biochar projects truly achieve long-term carbon sequestration and effectively mitigate the potential risks of low-quality projects. As a manufacturer of advanced biochar production equipment, we are committed to providing developers with sustainable, compliant, and scalable solutions. If you are planning to invest in a high-quality biochar CDR project, please contact us. Let us work together to build a greener and more reliable future.

.jpg)