System Diagram

Biomass Gasification

Multifunction Drying Waste Heat System

Multifunction Drying Waste Heat System

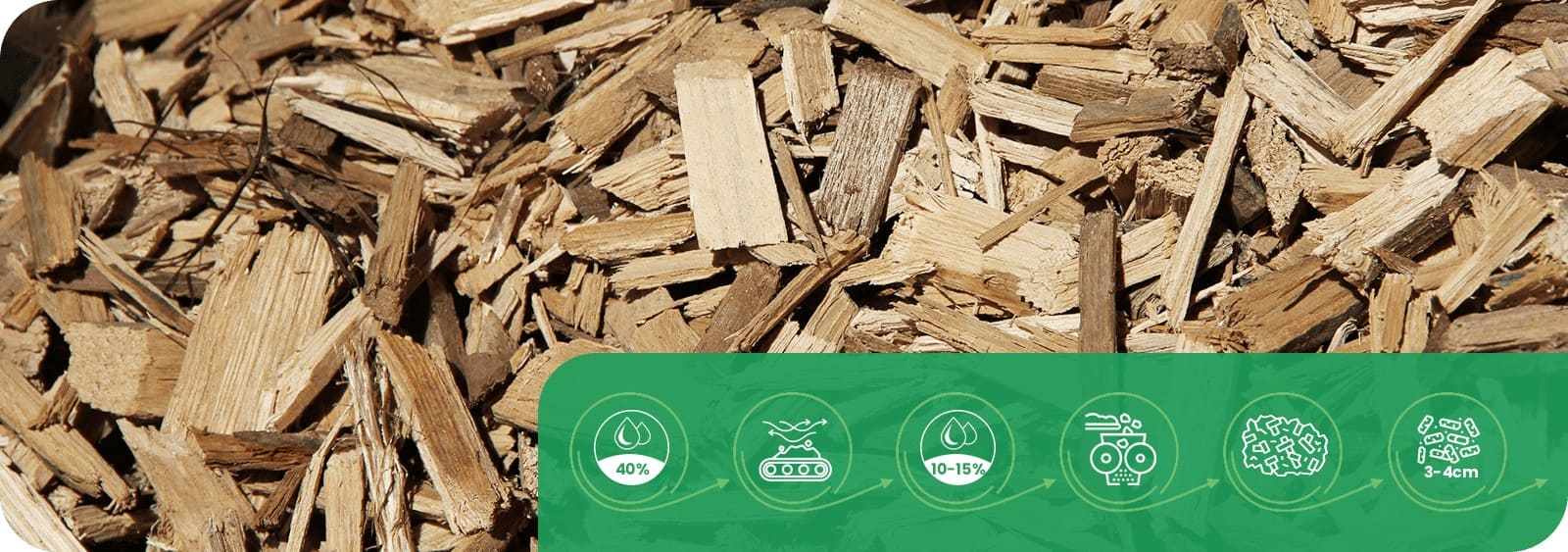

1. Crusher

2. Control Room

3. Grab Crane

4. Raw Material Room

5. Hot Air Pipeline

6. Automatic Feeding System

7. Gasification System

8. Gas Burner

9. Circulation Water Heat Exchange System

10. Dryer Feeding System

11. Drying System

12. Chimney

13. ID Fan

14. Bag Filter

15. Multi Tube Ceramic Dust Removal

1

Crusher

2

Control Room

3

Grab Crane

4

Raw Material Room

5

Hot Air Pipeline

6

Automatic Feeding System

7

Gasification System

8

Gas Burner

9

Circulation Water Heat Exchange System

10

Dryer Feeding System

11

Drying System

12

Chimney

13

ID Fan

14

Bag Filter

15

Multi Tube Ceramic Dust Removal

Combustible Gas Pipeline

Hot Air Pipeline

Tar Pipeline

Hot Water Pipeline

Cold Water Pipeline

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)