System Diagram

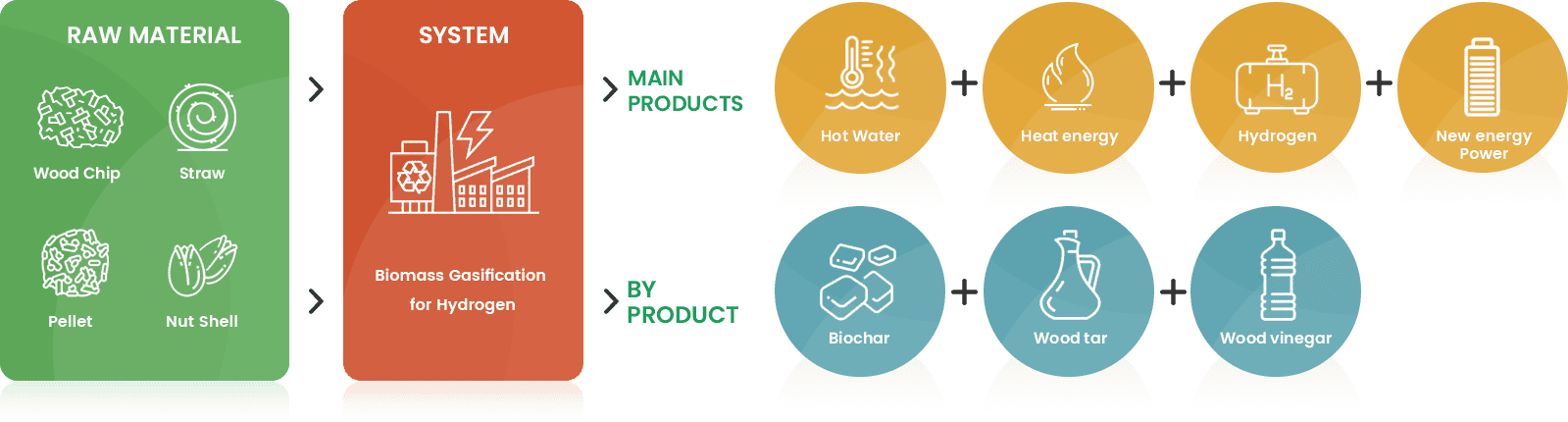

Biomass Gasification For Hydrogen System

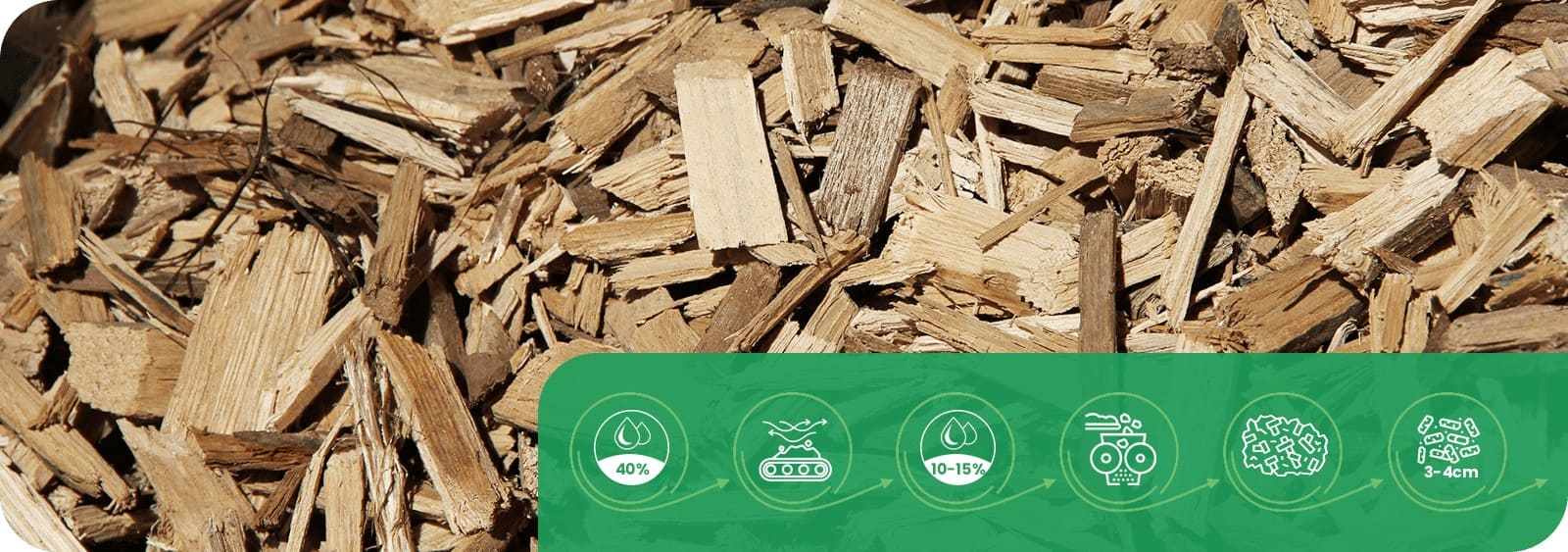

1. Crusher

2. Control Room

3. Grab Crane

4. Raw Material Room

5. Hot Air Pipeline

6. Circulation Water Heat Exchange System

7. Automatic Batching System

8. Gasification System

9. Combustible Gas Purification System

10. Underground Tar Tank

11. Air Compressor

12. Membrane Filtration

13. Gas Buffertank A

14. PSA Purification

15. Gas Relief Tank

16. 99.99% Hydrogen

17. Gas Distribution Tank

18. Gas Boiler

19. Internal Combustion Generator

1

Crusher

2

Control Room

3

Grab Crane

4

Raw Material Room

5

Hot Air Pipeline

6

Circulation Water Heat Exchange System

7

Automatic Batching System

8

Gasification System

9

Combustible Gas Purification System

10

Underground Tar Tank

11

Air Compressor

12

Membrane Filtration

13

Gas Buffertank A

14

PSA Purification

15

Gas Relief Tank

16

99.99% Hydrogen

17

Gas Distribution Tank

18

Gas Boiler

19

Internal Combustion Generator

Combustible Gas Pipeline

Hot Air Pipeline

Tar Pipeline

Hydrogen Pipeline

Hot Water Pipe

Cold Water Pipeline

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)