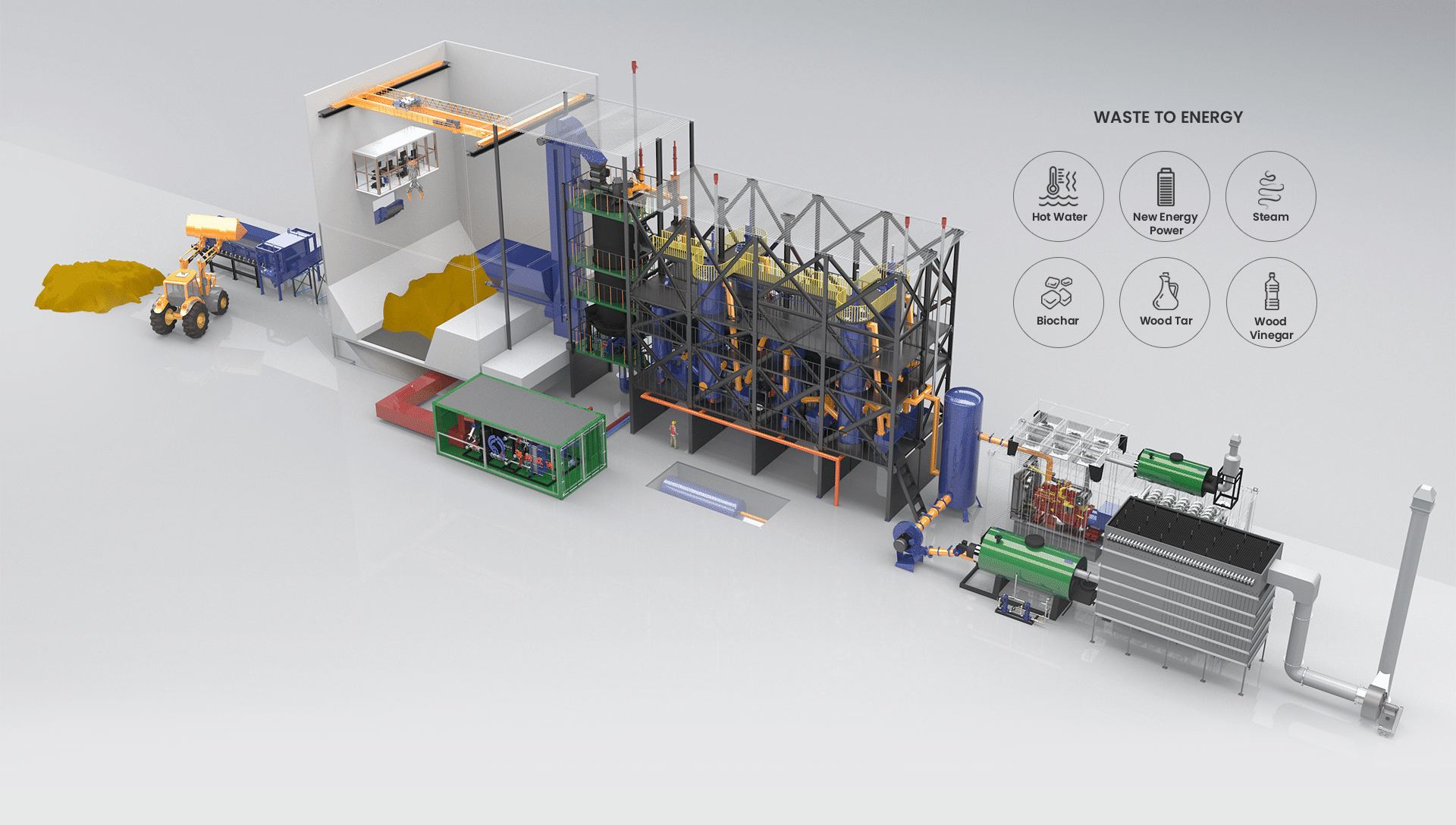

System Diagram

Biomass Gasification Poly- Generation System

1. Crusher

2. Control Room

3. Grab Crane

4. Raw Material Room

5. Hot Air Pipeline

6. Circulation Water Heat Exchange System

7. Gasification System

8. Combustible Gas Purification System

9. Underground Tar Pipeline

10. Underground Tar Tank

11. 0peration Room

12. Gas Id Fan

13. Gas Burner

14. Gas Boiler

15. Gas Buffer Tank

16. Internal Combustion Generator

17. Waste Heat Utilization System

18. Bag Filter

19. ID Fan

20. Chimney

1

Crusher

2

Control Room

3

Grab Crane

4

Raw Material Room

5

Hot Air Pipeline

6

Circulation Water Heat Exchange System

7

Gasification System

8

Combustible Gas Purification System

9

Underground Tar Pipeline

10

Underground Tar Tank

11

0peration Room

12

Gas Id Fan

13

Gas Burner

14

Gas Boiler

15

Gas Buffer Tank

16

Internal Combustion Generator

17

Waste Heat Utilization System

18

Bag Filter

19

ID Fan

20

Chimney

Combustible Gas Pipeline

Hot Air Duct

Tar Pipeline

Hot Water Pipeline

Cold Water Pipeline

Flue Gas Pipeline

.png)

.gif)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)