Generation System

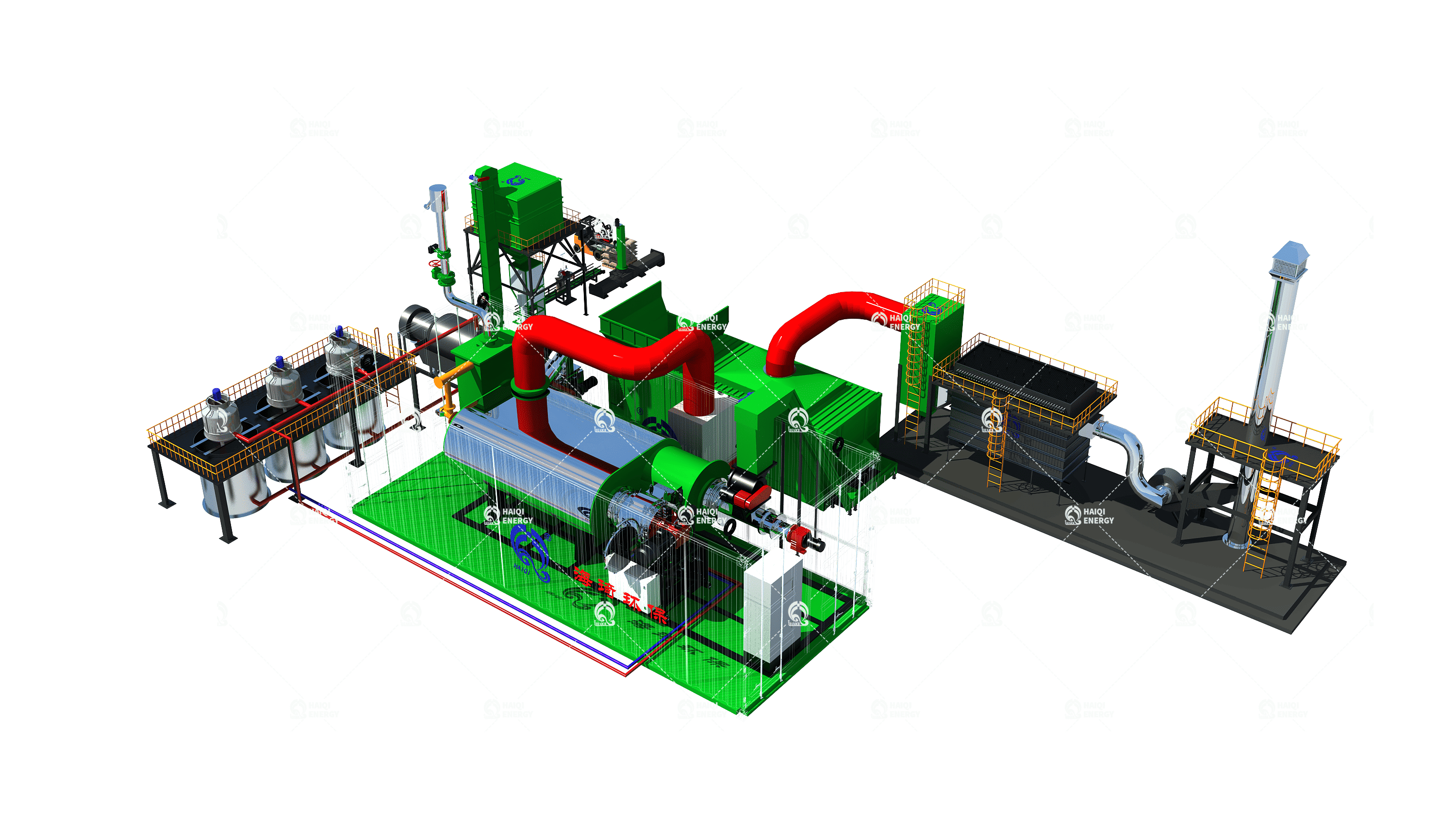

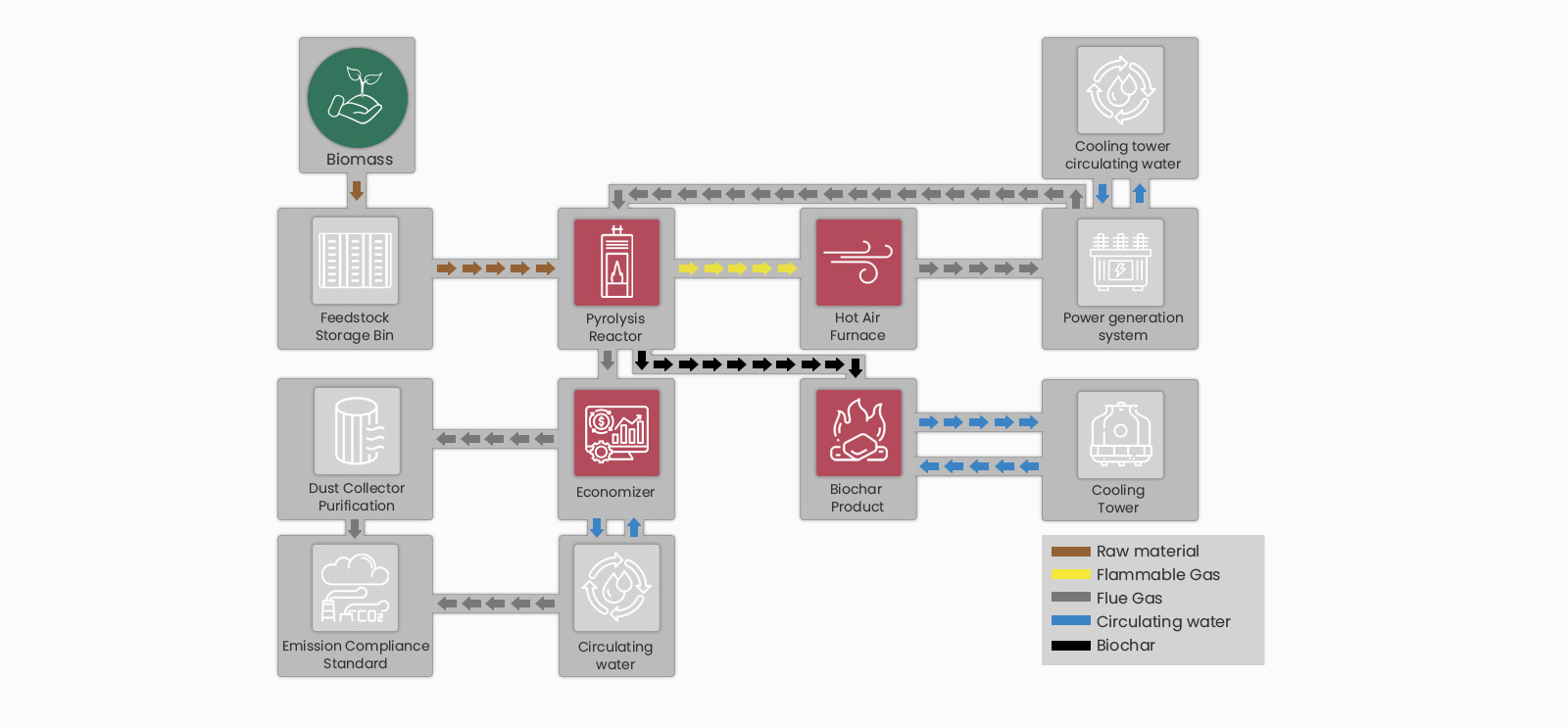

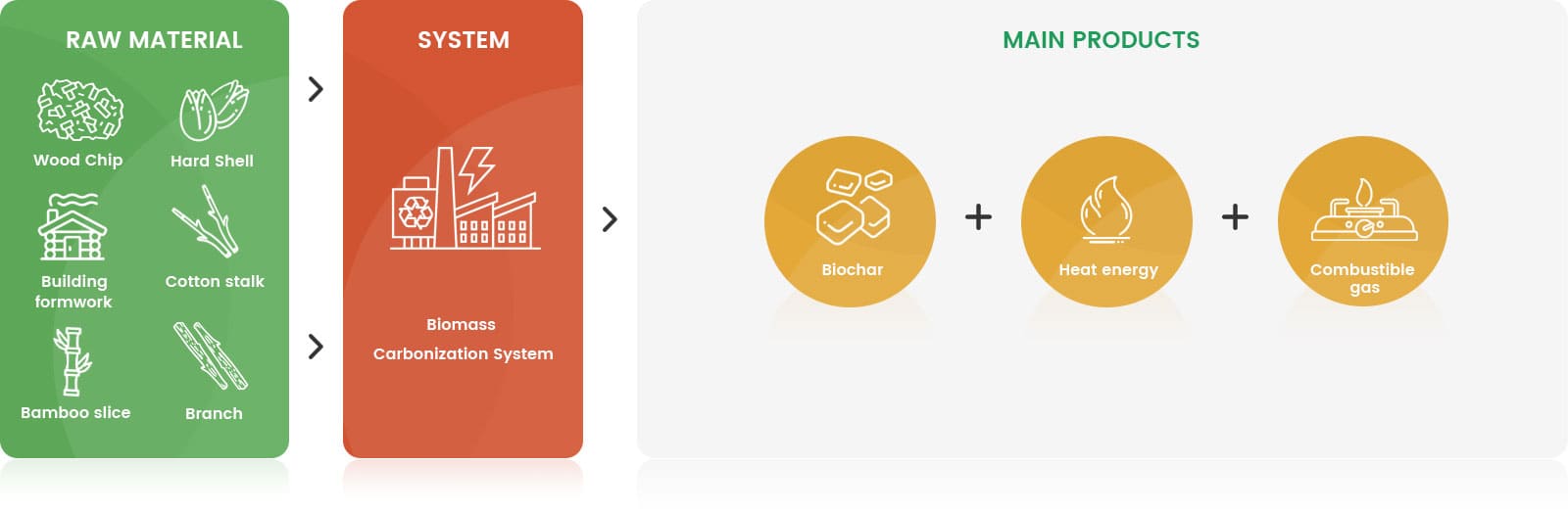

Biomass Pyrolysis Carbonization Drying Power Generation System

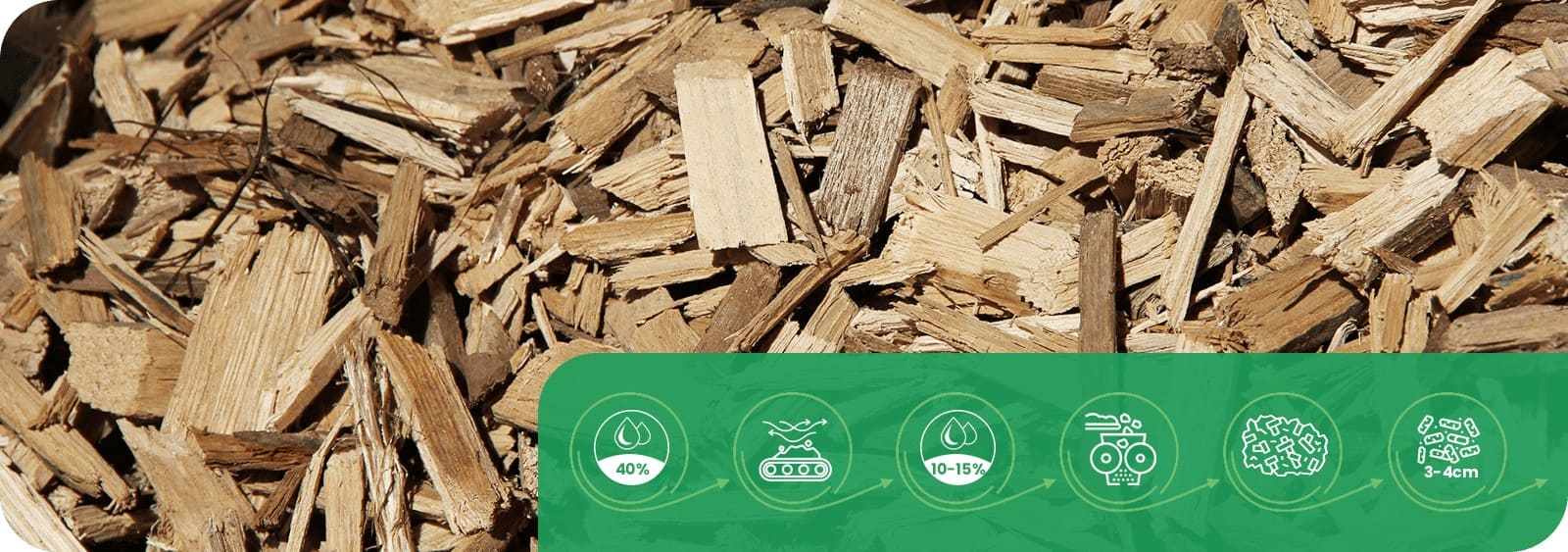

1. Drying and storage silo

2. Multi-tube ceramicdust collector

3. Bag dust collector system

4. Chimney

5. Economizer

6. Pyrolysis carbonization system

7. Hot blast stove

8. Stirling generator

9. Control system

10. Cooling tower

11. Biochar cooler

12. Biochar packaging system

1

Drying and storage silo

2

Multi-tube ceramicdust collector

3

Bag dust collector system

4

Chimney

5

Economizer

6

Pyrolysis carbonization system

7

Hot blast stove

8

Stirling generator

9

Control system

10

Cooling tower

11

Biochar cooler

12

Biochar packaging system

.png)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)