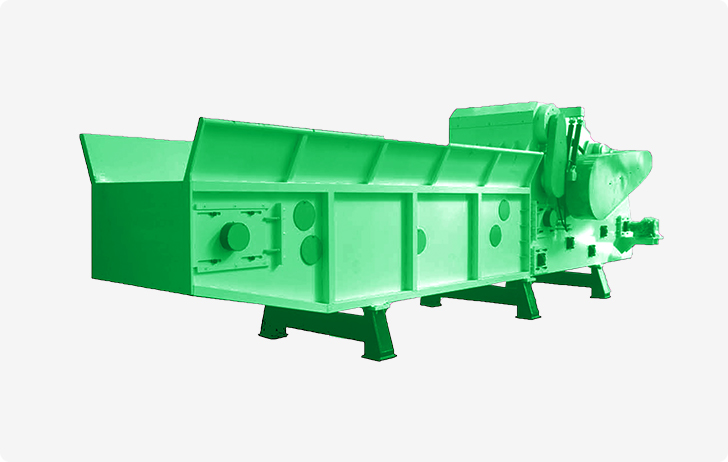

| Model | Yield(t/h) | Motor Power(kw) | Feed Size(mm) | Chip Size(mm) |

| HQPJ216 | 4-6* | 55+3+4+1.5 | 545*230 | 30-1100 |

| HQPJ218 | 6-10* | 110+5.5+5.5+1.5 | 710*360 | 30-1100 |

| HQPJ2113 | 12-25* | 315+11+11+3 | 1100*530 | 30-1100 |

| HQPJ300-300 | 6-10* | 110+5.5+5.5+1.5 | 1300*300 | 30-1100 |

| HQPJ300-600 | 12-25* | 160+7.5+7.5+3 | 1300*600 | 30-1100 |

| HQPJ1400 | 15-20* | 220+7.5+7.5+3+3 | 1400*600 | 30-1100 |

| HQPJ1650 | 18-25* | 220+11+7.5+3+4 | 1650*600 | 30-1100 |

| Overall size | L9350MM/W2540MM/H3480MM |

| Walking /driving types | Hydraulic front wheel drive Rear-wheel steering |

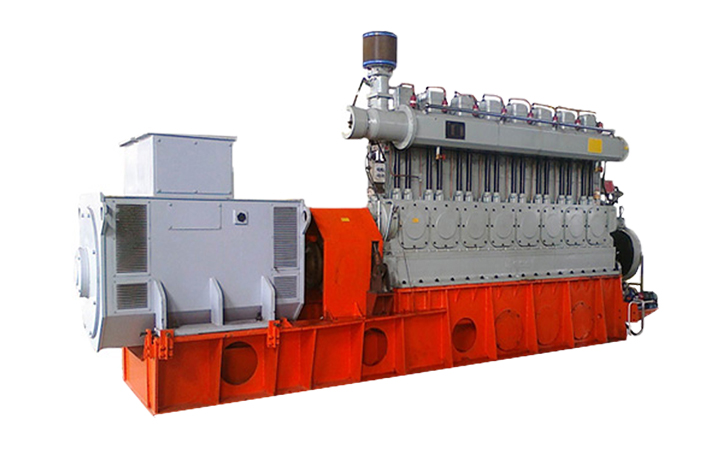

| Engine brand / model | Yuchai YCA08300-T301 Weichai WP7 |

| Engine power | 221KW/300HP |

| Combined fuel consumption for standard operation | 26L/T |

| Travel speed | Variable speed, up to 40KM/H |

| No-load weight of the machine | <8500KG |

| Load capacity of finished material tank | ≈3.8M³ |

| Horizontal/longitudinal wheel base | 2500mm/3200mm |

| Tyre specification | Drive wheels 500/60-22.5 Steering wheels 409/60-15.5 |

| Pickup type | Scrap suction pickup Ground clearance is adjustable |

| Pick up width | 2200mm |

| Ground clearance | 380mm |

| Standard operating efficiency (Fuel RL and Feed SL) | RL:1.3T/H SL:1.5T/H |

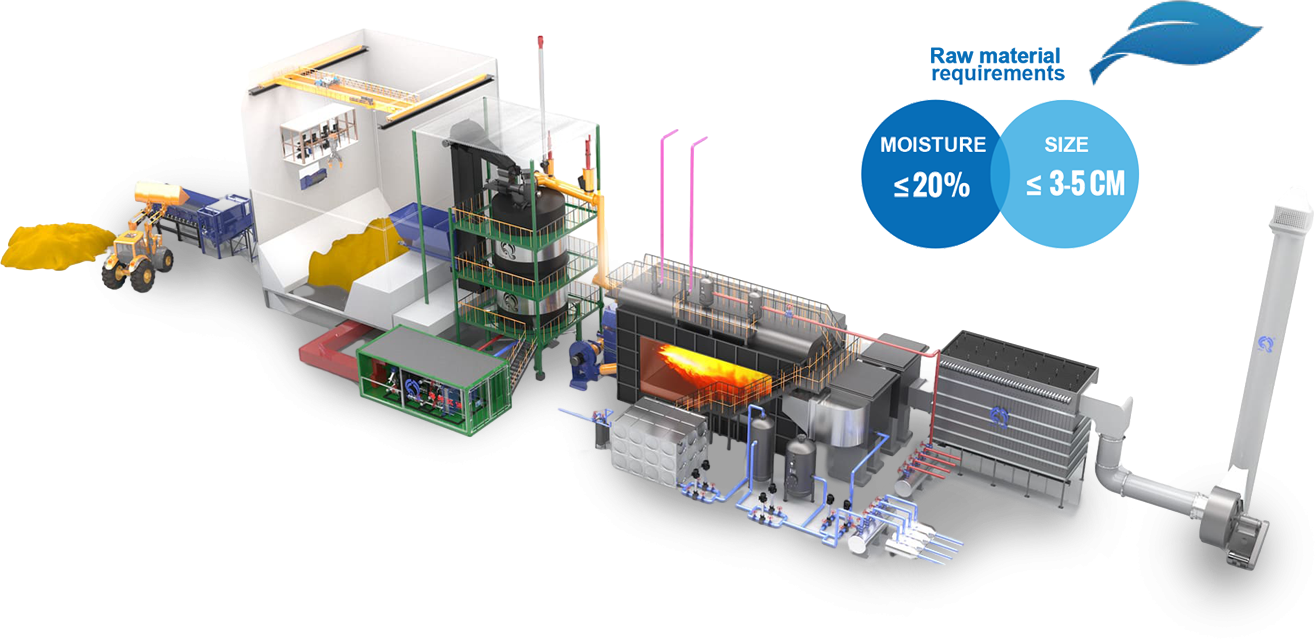

| Raw material moisture requirement | 10%≤RL≤30% 10%≤SL≤25% |

| Conventional pellet density | RL≥1.0g/cm³ SL≥0.7g/cm³ |

| Conventional soil content of pellet | RL≤5% SL≤3% |

| Conventional moisture content of pellet | RL≤15% SL≤20% |

| Corn stalk fuel pellet combustion value | RL≥3500CAL |

| Method and duration of discharge of finished pellet | No stop/stop unloading time is about 4 minutes |

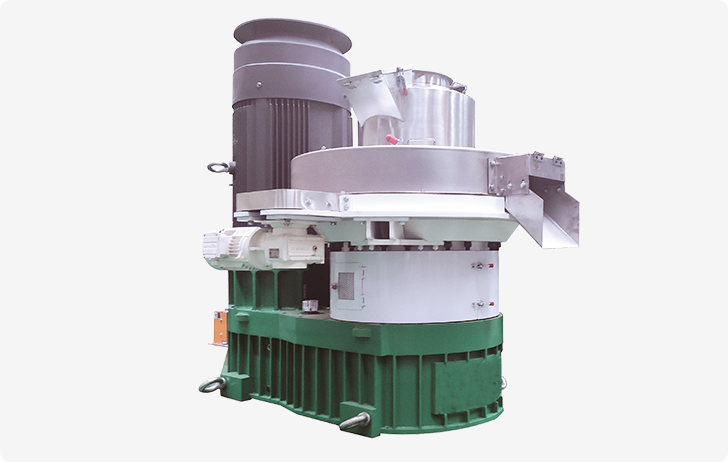

| Overall size | Capacity(t/h) | Motor power(kw) | Overall dimension(mm) |

| HQPJ216 | 1-2* | 90/110/132 | 2200*1280*1640 |

| HQPJ218 | 2-3* | 120/220 | 2450*1400*1950 |

| HQPJ2113 | 3-4* | 220/250 | 2450*1400*1950 |

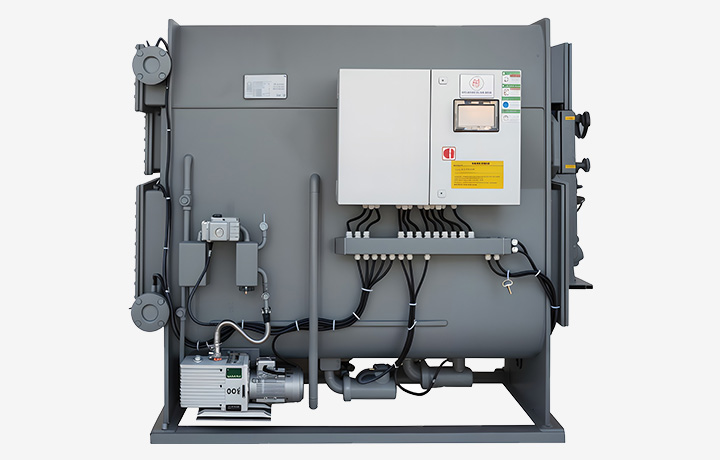

| Power | 30kW |

| Air consumption/hour | 10Nm3/30kWhe |

| Air supply pressure | 3-5bar |

| PCU Efficiency (gas-electric conversion) | >30% |

| Output voltage | 400V three-phase, grid quality |

| Frequency Hz | 50/60Hz |

| Cogeneration efficiency | >80% |

| Dimensions | 1.35x0.9x1.0m |

| Weight | 750kg |

| Inlet gas temperature≤40℃ | Gas pressure 2.5~10kPa |

| Pressure change rate≤1kPa/min | Heating value of gas>4.0MJ/Nm³ |

| Moisture content≤40g/Nm³,no free wate | Dust content≤30mg/Nm³ |

| Dust size≤5um³ | Tar content≤50mg/Nm³ |

| Hydrogen sulfide content≤50mg/Nm³ | Total sulfur content≤100mg/Nm³ |

| Ammonia content≤20mg/Nm³ | Oxygen content≤50mg/Nm³ |

| Hydrogen volume content≤50% | Oxygen volume content≤1% |

|

Model |

CNBC-300 |

CNBC-500 |

CNBC-1000 |

|

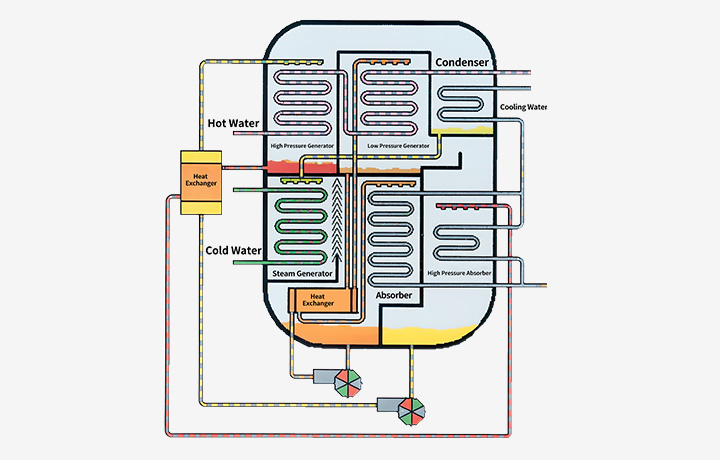

System waste heat |

1.72 million kcal |

2.87 million kcal |

5.74 million kcal |

|

Hot water flow (90℃/85℃) |

344m³/h |

574m³/h |

1148m³/h |

|

Chiller unit |

RXZ-350 unit *4 sets |

RXZ-350 unit *6 sets |

RXZ-350 unit *13 sets |

|

Cold water flow (15℃/10℃ or 12℃/7℃) |

240m³/h |

360m³/h |

780m³/h |

|

Refrigerating capacity |

1400Kw |

2100Kw |

4550Kw |

|

Cold water flow (30℃/35℃ or 29℃/34℃) |

600m³/h |

900m³/h |

1950m³/h |

|

Model |

CNBC-300 |

CNBC-500 |

CNBC-1000 |

|

Heat absorption by drying (50% to 15% water content in raw material) |

0.32 million kcal |

0.54 million kcal |

1.08 million kcal |

|

System waste heat |

1.40 million kcal |

2.33 million kcal |

4.66 million kcal |

|

Hot water flow (90℃/85℃) |

280m³/h |

466m³/h |

932m³/h |

|

Chiller unit |

RXZ-350 unit *4 sets |

RXZ-350 unit *6 sets |

RXZ-350 unit *13 sets |

|

Cold water flow (10℃/15℃) |

180m³/h |

300m³/h |

660m³/h |

|

Refrigerating capacity |

1050Kw |

1750Kw |

3850Kw |

|

Circulating water flow (39℃/44℃) |

450m³/h |

750m³/h |

1650m³/h |