Generation System

Biomass Pyrolysis Waste Heat Recovery Equipment

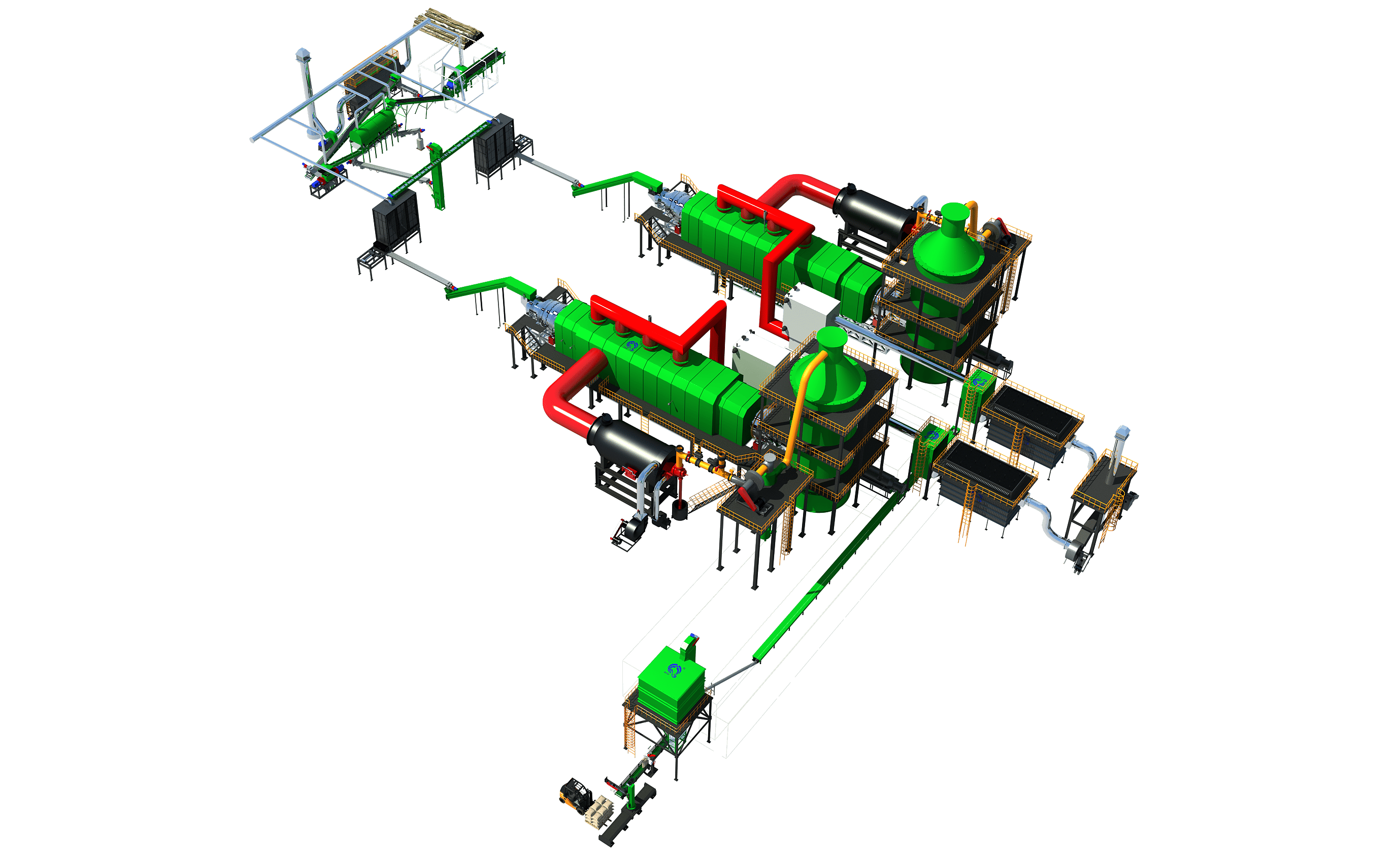

1. Wood chipper

2. Dust collector

3. Screening machine

4. Raw material silo

5. Feeding belt of the pyrolysis furnace

6. Pyrolysis carbonization system

7. Economizer

8. Low nitrogen burner

9. Hot blast stove

10. Precipitator

11. Biochar auger

12. Biochar cooler

13. Bag dust collector system

14. Chimney

.png)

1

Wood chipper

2

Dust collector

3

Screening machine

4

Raw material silo

5

Feeding belt of the pyrolysis furnace

6

Pyrolysis carbonization system

7

Economizer

8

Low nitrogen burner

9

Hot blast stove

10

Precipitator

11

Biochar auger

12

Biochar cooler

13

Bag dust collector system

14

Chimney

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)