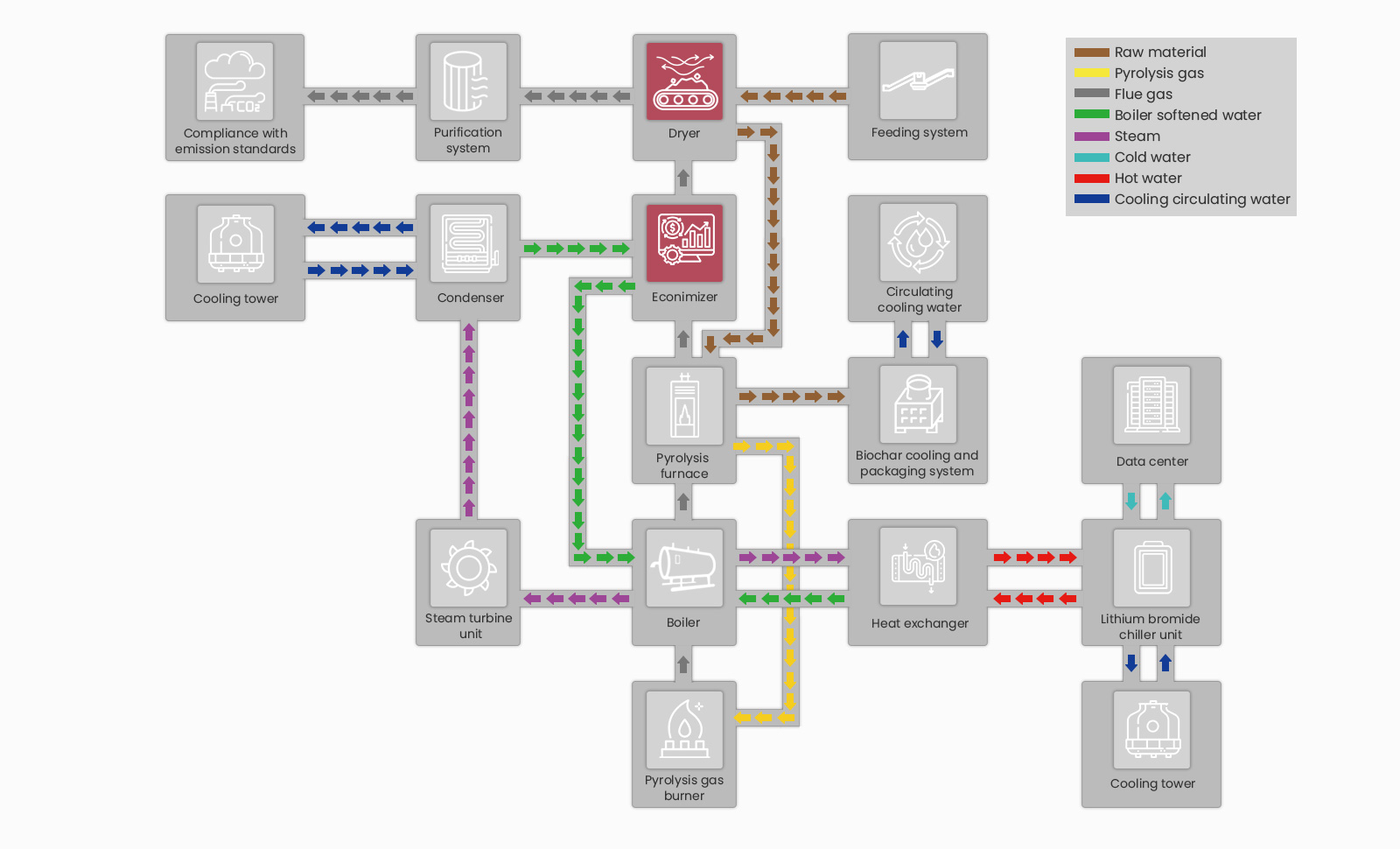

System Diagram

Biomass Pyrolysis Power Plant in Data Center-CNBC

1. Preprocessing system

2. Silo

3. Precipitator

4. Heat exchanger

5. Biochar automatic packaging system

6. Steam turbine generator set

7. Cooling tower

8. Switch room

9. Steam header

10. Chimney

11. Bag filter dust collector

12. Multi-cyclone ceramic dust collector

13. Drying system

14. Pyrolysis system

15. Gas-fired boiler

16. Biochar cooling machine

17. Data center

18. Lithium bromidere frigeration equipment

.png)

1

Preprocessing system

2

Silo

3

Precipitator

4

Heat exchanger

5

Biochar automatic packaging system

6

Steam turbine generator set

7

Cooling tower

8

Switch room

9

Steam header

10

Chimney

11

Bag filter dust collector

12

Multi-cyclone ceramic dust collector

13

Drying system

14

Pyrolysis system

15

Gas-fired boiler

16

Biochar cooling machine

17

Data center

18

Lithium bromidere frigeration equipment